Difference between revisions of "Construction"

(→Metalworking Tools) |

(→Metalworking Tools) |

||

| Line 33: | Line 33: | ||

* Center punch | * Center punch | ||

* Blow Torch - MAP Gas works best, Propane as a second choice | * Blow Torch - MAP Gas works best, Propane as a second choice | ||

| + | |||

A '''Metal Brake''' is useful for bending sheet steel to make brackets. | A '''Metal Brake''' is useful for bending sheet steel to make brackets. | ||

Revision as of 23:02, 8 January 2015

Once a preliminary design is complete, the next step is to create an initial prototype, known in the industry as a Whitewood.

Whitewood

The origin of the term whitewood is related to the material of the playfield, which is traditionally White Maple. The first iteration of a game will not have any artwork or lighting as the purpose is to test the layout, flipper shots and the overall feel of the design to confirm it plays as expected.

The second iteration of the whitewood - generally a different playfield rather than the existing one re-cut - will include inserts, lighting and any ramps or playfield devices needed for the complete game. This version of the prototype is used to create the first iteration of the ruleset and special effects.

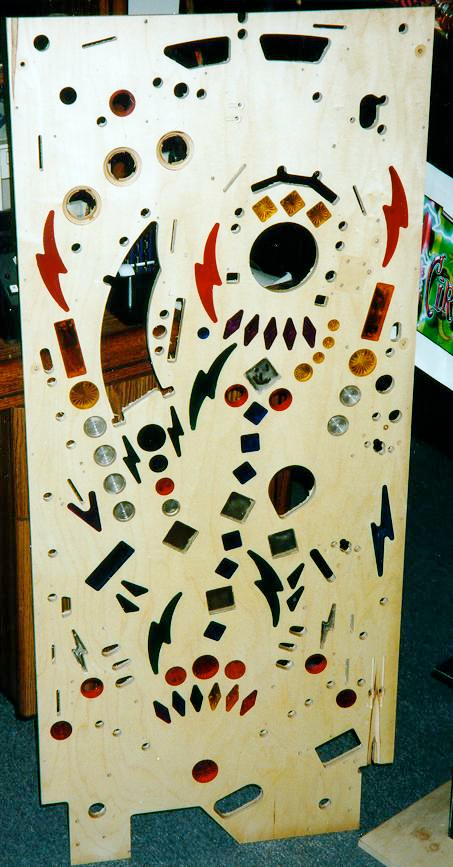

Here is an unpopulated whitewood for Cirqus Voltaire, which is a later iteration that does have inserts for lighting, but not yet having artwork.

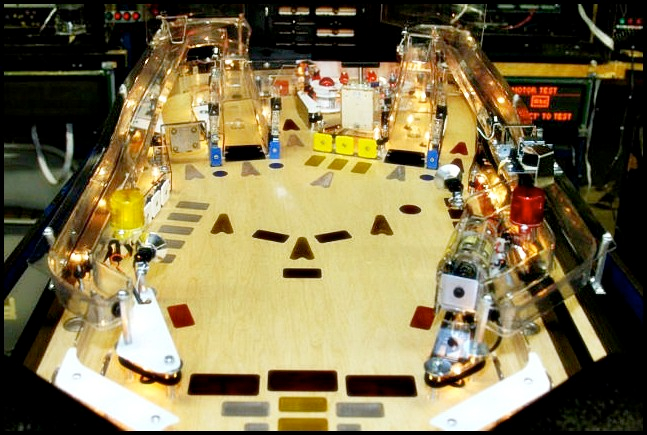

Here is a populated whitewood for AC/DC, which does not have the later sub-playfield so is much earlier in the design process.

Tools

Metalworking Tools

- A few different colored sharpies for marking cuts and bends

- 4 1/2" angle grinder for cutting and grinding

- Flap disc grinding pads of multiple grits

- Metal cutting blades for a grinder

- Safety glasses and gloves

- A bunch of different size C-clamps - at least one large and two big enough to clamp large items

- A Square

- Measuring tape

- Different sized ballpein hammers

- Drill bits for steel

- Center punch

- Blow Torch - MAP Gas works best, Propane as a second choice

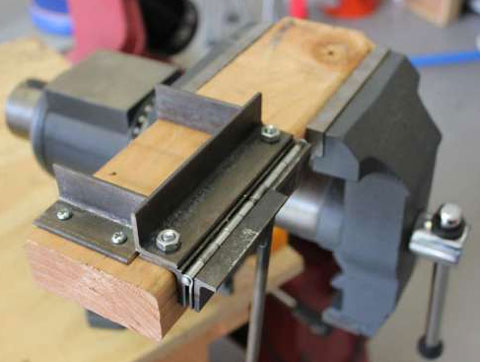

A Metal Brake is useful for bending sheet steel to make brackets.

The above example is available from Harbor Freight.

If space is at a premium, there are smaller tabletop versions as well.

If cost is an issue, you can make your own from common hardware store parts.

Woodworking Tools

Beyond the standard hand tools needed to create a machine from scratch, here are some additional tools:

A Hand Router for creating insert and device holes in the playfield.

A Table Jigsaw for cutting playfield plastics, or plexi for your initial whitewood inserts.

A Hand Sander to level the playfield. You should also have sand paper in various grits ranging from 180 up to 320, plus finer grits for final polishing.

Forstner bits for drilling clean holes. Easier than using the router.

Cabinet Tools

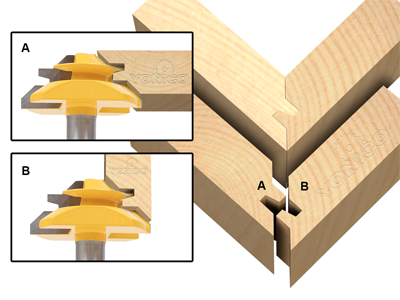

For cabinet building, a table router with Locking Mitre bits.

It is a bit that creates a locking edge between cabinet corners.

Advanced Tools

Although not strictly needed for hobbyists, the following are nice-to-have if you have some deep pockets, and they make whitewood production much faster and far more consistent. Rather than purchasing these, the best option is to find a local Maker Space that has the equipment available for rent or through a monthly membership.

A large-format CNC machine can take drawings from AutoCAD or Inkscape to cut a playfield exactly to the design, which will be much more accurate than one done by hand with a router.

Some reasonably-priced options include ShopBOT or GeneralCNC. There are smaller ones available in the $2K range but they won't be large enough to cut a full playfield.

Using a laser cutter on plastics means fast prototyping of playfield plastics, and most cutters will also do engraving for interesting effects. Really high powered units will cut wood as well.

Some examples include Epilog and Universal.

A lower cost option is the Full Spectrum Laser.

Materials

A rundown of the various materials needed to produce a whitewood.

Plywood

Commercial pinball machines use a specially sourced type of plywood that is not available from big box stores and generally not even specialty wood suppliers.

The thickness of a raw playfield is 17/32", which is then sanded on top with inserts installed to a finished size of 1/2". Each side is a full face of hard Maple with five plys in-between, not a thin veneer to allow for this sanding. The following photo illustrates the full seven plys:

The type of plywood available at a big box store will have a thin ply on both sides, generally of softer Baltic Birch, and will not have the surface area to allow a full 1/32" sanding to level the surface and inserts together.

For hobbyists, the best option is Cabinet Grade plywood, preferably from a lumber yard, with a minimum of seven plys but a preference for nine - the more plys, the more stable and flat. This type of plywood will have a thicker top and bottom ply suitable for sanding. It will generally be the softer birch but for one-off games, it should prove acceptable.

Another affordable option for whitewoods is Medium Density Fibreboard. Typically sold as MDF, it is also available in large quantities. The drawback for MDF is that it has poor flexibility and does not allow for easy removal and re-installation of screwed in parts.

Inserts

For a whitewood, the easiest option is to use thin plexiglass for inserts as it is readily available and fairly easy to cut to size with a table jigsaw. This allows for skipping the final sanding stage if using 1/2" plywood instead of 17/32".

Real pinball inserts are available in various sizes and colors from a number of suppliers including Pinball Resource and Marco Specialities.

Some examples of the inserts available:

5/8″ round White opaque #PI-58RW

1-1/2″ triangle Green #PI-112TGT

Rollover star button housing red 3A-7537 #C-901

Standard depth of inserts are 1/4" and they are designed to be sanded flat after installation - there will be a number cast into the top of the part and the top edge will be slightly raised around the radius by approximately 1/32". Thus, when creating insert holes, you must drill slightly less than 1/4" deep to allow for the sanding.

Playfield Parts

The best source of parts like switch targets, pop bumpers, posts and other miscellaneous bits is from parts machines - picking up a used machine with a worn playfield and just cleaning up those parts will be ten times cheaper than buying all new parts.

However, given the increasing value of even older solid-state machines, finding games to part out is becoming increasingly difficult, so the only option may be purchasing new.

Electronics

Once the physical playfield is constructed, wiring it all together and adding a way to control the devices will be required. There are three basic options - use existing pinball boards, build custom control boards or purchase off-the-shelf units.

Existing Boards

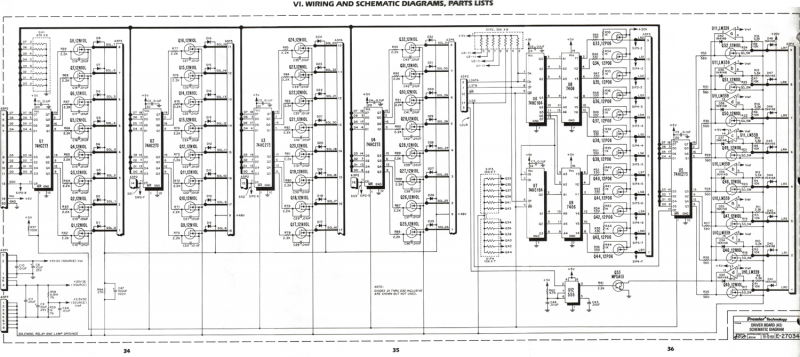

A popular option is using boards from existing machines and replacing the main controller. For example, the Gottlieb System 3 driver board uses modern MOSFET drivers, supports 32 coils and a 8x10 lamp matrix, and is available for $100 from Pinball Resource.

Another well documented system is the original Bally system.

Custom Boards

TBD

Off-the-Shelf Boards

P-ROC (Pinball - Remote Operations Controller) is a well-supported generic platform that is in use by many custom games. It has a dedicated forum.

FAST Pinball is the new kid on the block that will be bringing out a controller in 2015.

Both of those systems require an external PC with USB to provide the signals to control the solenoids and lamps. Currently these small ARM-based boards are the best candidates as they are more powerful than the Raspberry Pi or Arduino boards:

O-DROID : Quad-core CPU, dual-core GPU, 1GB DDR3 RAM, Gigabit Ethernet , 4x USB2.0 ports.

Beaglebone Black: AM335x 1GHz ARM® Cortex-A8, 512MB DDR3 RAM, 4GB 8-bit eMMC on-board flash storage

Wiring

Prototyping

Many hobbyists plan on producing games with game-specific features that aren't included in other machines, such as ramps or ball control devices, and thus will have to design and construct mechanisms from scratch. This generally involves metalworking and other more advanced skills, but are not beyond the garage hobbyist.

Ramps and Multi-Levels

Wireforms

One standard convention on modern pinball machines are wireform ramps. They can be made out of 1/8" steel wire which can be purchased at most big box stores.

Welding vs. Brazing

It is recommended to use a flux cored wire feed MIG Welder when making wireforms.

Propane Brazing is a lot easier and can be done with hand tools, but it requires a lot of heat for a long period of time in one spot, which weakens the surrounding steel. This makes it more susceptible to warping and bending due to stress. It can work, but it is not nearly as strong as MIG.

Spacers

Spacers help to keep the proper distance between two rails in a wireform while it is being constructed. They can also be used for welding braces. A fair number of these will be needed - two or three per curve - plus a few oversized ones to allow for the grounding clamp from the welder if you're using one.

To make them, just measure the ball and figure out where you want the ball to ride in the rail, then drill two holes the same size as the stock you are planning on using.

Slide the spacers on and match the other wires bends carefully. Make sure to only bend the new wire and not the guide wire.

Use 16 and 20 gauge sheet metal for the spacers - 20 for tight bends and 16 for straightaways. It is easier to slide the 20 gauge down the curves.

If skinning wireforms, put supports on the under side to make them stronger. You can construct ramps by welding sheet metal over the tops of the rails at the ball entry points.

Loops

Loops are useful as entrance and exit points, and cut down can be used as bracing.

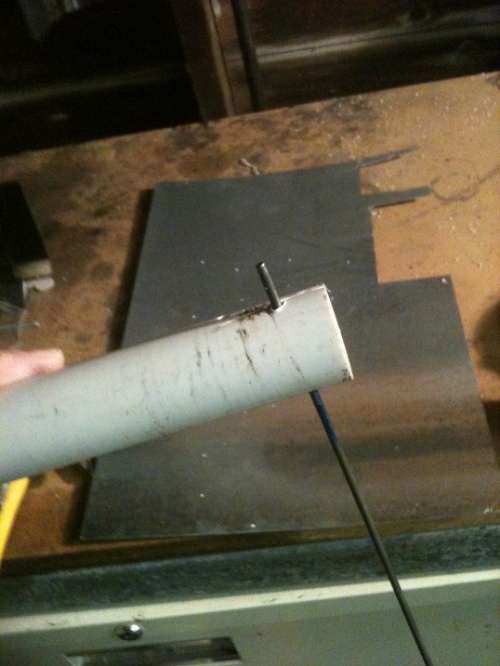

Take a piece of 1" PVC pipe and drill a hole centered on the pipe all the way through, roughly the same size of the stock that you intend to use.

Insert the stock all the way through and wrap it around really tightly. It will spring back a little, but if you are using a standard size pinball, it shouldn't be a problem as long as you keep the tension consistent all the way through the wrap.

With an Angle Grinder with Metal Cutting disc, cut as close to the initial bend to get as many loops as you can with out getting any of the curve in the cut.

Take caution! This is a dangerous tool!

A simple way to get really nice and easy loops.

Create supports by cutting the rings in half to make the supports. A large Side Cutter makes cutting the 1/8" steel stock easy and fast - just make sure to hold on to both pieces because they can fly apart. Eyeball guessing for the center on the rings is fine, but for consistency, measure for center.

Drawings

After making spacers and loops, the best starting point is using drawings made in one of the drawing tools mentioned in the Design section. Match the form to the full-size 2D drawing during construction.

Welding

Cut a straight piece of stock, place it on the end of the rail and weld it up with a good tack. This will stop the wireform from twisting out of shape while putting the supports on. Use Welding Magnets (Usually about $3 each from most hardware stores) to hold the wire in position.

Clamp the ground for the welder to one of the jigs - you get a good, dependable circuit and it won't mess you up when you move it.

Time to weld!

Only weld with a Welding Helmet that is tight and won't fall off. If using a auto-darkening helmet, test its function before starting to weld. It should darken from the spark of a lighter.

First test the feed of the welder by pushing the button and watching how smooth the wire comes out. Having a jumpy feed can ruin a weld pretty fast. Then trim the wire to a comfortable length.

If the wire is too long, it will make spatter all over, while if too short, it could miss the joint and/or clog up the tip of the welder.

A good weld has clear signs of even heating and penetration through both parent metals (the grayish circle that surrounds the weld).

The bad weld example was done by having the wire overfed or having the wand to far from the surface. This creates a large amount of spatter, which on pinball rails is difficult to clean up due to the sizing.

It also has a distinct noise when done incorrectly - it sounds like bacon popping. A good weld has a consistent buzz sound.

After measuring where you want each support to go on the wireform, flip the rail over and set a half ring that was cut earlier across the two rails, using a magnet to hold it in place.

Make sure the ring is lined up with both sides of the rail. It should flow with curves and should be evenly placed.

A good welding technique to use is called Pushing the puddle. It is basically starting on the thicker material and pushing the molten puddle back into the thinner cross material.

Top Rail

With all the supports are welded, it's time for the top rails.

Take the PVC pipe used to make the rings from earlier and mount it to your workbench. Put the stock where the bend should be under the pipe and pull up, keeping a lot of force at the base.

Take the bent stock and lay it across the rail. Mark where it should get the first welds.

Go down the entire length of the wireform, bending the top rail wire by hand as close as possible to the form without welding. Welding and bending one after the other would cause the areas that have been welded to be much softer from the heat of the weld. This is called Tempering, and your top rail bends will not match the cold bended main rail.

Finishing

Every now and then, bring your wireform back to the machine and test fit to make sure it is not getting warped from the heat of the welder.

During the fitting, mark areas for adding supports to hold the wireform.

After all the welding is complete, quickly run the whole wireform on a Fine Finishing Wire Wheel to clean it up and ready it for powdercoating or plating.