Construction

Once a preliminary [Design|design] is complete, the next step is to create an initial prototype, known in the industry as a Whitewood.

Contents

Whitewood

The origin of the term whitewood is related to the material of the playfield, which is traditionally White Maple, hence the white. The first iteration of a game will not have any artwork or lighting as the purpose is to test the layout, flipper shots and the overall feel of the design to confirm it plays as expected.

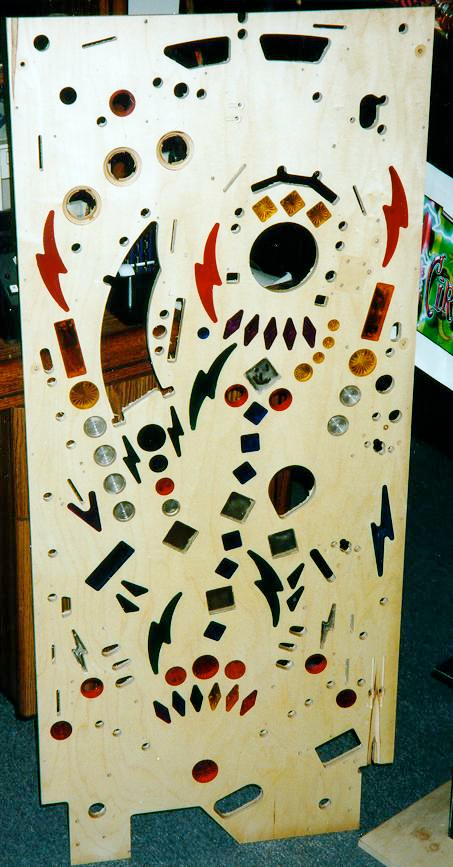

Here is an unpopulated whitewood for Cirqus Voltaire, which is a later iteration that does have inserts for lighting, but not yet having artwork.

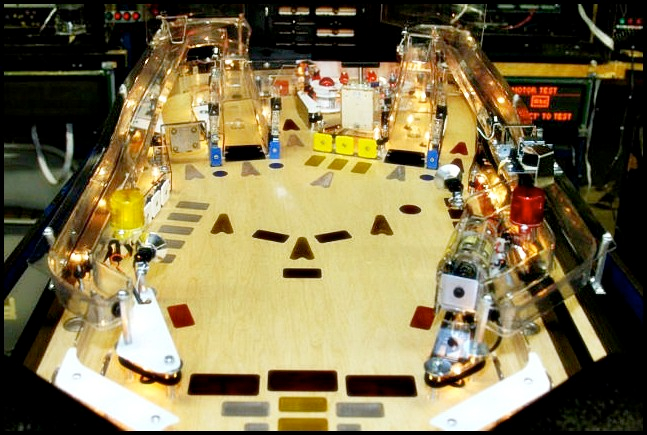

Here is a populated whitewood for AC/DC, which does not have the later sub-playfield so is much earlier in the design process.

Plywood

Commercial pinball machines use a specially sourced type of plywood that is not available from big box stores or even specialty wood suppliers. As of this writing, only two mills are known to produce it, one of which supplies Churchill for use in Stern games, and the other for Classic Playfield Reproductions. Minimum orders are around 1,000 4x8 sheets - well beyond the average hobbyist.

The thickness of a raw playfield is 17/32", which is then sanded on top with inserts installed to a finished size of 1/2". Each side is a full face of hard Maple with five plys in-between, not a thin veneer to allow for this sanding. The following photo illustrates the full seven plys:

The type of plywood available at a big box store will have a thin ply on both sides, generally of the softer Baltic Birch, and will not have he surface area to allow a full 1/16" sanding to level the surface and inserts together.

However, many hobbyists make use of it due to the ease of availability and for a one-off game is perfectly acceptable. Another affordable option for whitewoods is Medium Density Fibreboard - MDF - also available in large quantities.

The drawback for MDF is that it has poor flexibility and does not allow for easy removal and re-installation of screwed in parts.