Difference between revisions of "Construction"

(→Devices) |

|||

| Line 829: | Line 829: | ||

To see these parts powder coated and installed, see the ''DeadPin'' machine in the [[Custom_Games]] section. | To see these parts powder coated and installed, see the ''DeadPin'' machine in the [[Custom_Games]] section. | ||

| − | === | + | ==== Stencil Cutter ==== |

| + | |||

| + | A '''Stencil Cutter''' is similar to a computer printer, except instead of printing it uses a small blade to cut paper, cardstock, vinyl, fabric, and other material. A good quality unit is the '''[http://www.silhouetteamerica.com/shop/machines/cameo Sihouette Cameo]''', available from Amazon. | ||

| + | |||

| + | There are two steps to creating quality stencils: | ||

| + | |||

| + | * The stencil material to cut with the Cameo | ||

| + | * The transfer tape used to transfer the weeded stencil to the part being painted | ||

| + | |||

| + | |||

| + | '''Weeding''' is the process where you remove the parts of the cut stencil you don't need. The best material to use is '''[http://cricketvinylsupplies.com/gerbermask-I-ultra-stencil-film-paint-mask-14-x-1-yd Gerber 15 SM-4 GERBERMASK 1 ULTRA]''' as it is thick enough to not clog the Cameo but allows for very fine detail. This is a medium tack pressure sensitive stencil material that has a slightly grainy white surface. It has a pressure-sensitive adhesive designed to work with a float solution like water with dish soap. | ||

| + | |||

| + | For the transfer tape, use '''[http://www.uscutter.com/RTape-Clear-Choice-AT65-All-Purpose-Medium-Tack-Application-Tape-100yd RTape Clear Choice AT65]''' which is a good general-purpose medium tack tape. | ||

| + | |||

| + | If working with an existing part, use a scanner to get a 1:1 image of the item to allow for vector tracing. Then bring the scan into a vector editor like '''Illustrator''' or '''Inkscape''', and create the vector outline of where the cuts should be made for the stencil. | ||

| + | |||

| + | [[Image:stencil-cut-1.jpg|300px]] | ||

| + | |||

| + | Once the vector is complete, the drawing can be imported into the ''Silhouette'' software bundled with the cutter to create a cut plot. | ||

| + | |||

| + | [[Image:stencil-cut-2.jpg|300px]] | ||

| + | |||

| + | At that point, the stencil can be cut and weeded. | ||

| + | |||

| + | [[Image:stencil-cut-3.jpg|300px]] | ||

| + | |||

| + | Apply the transfer tape to the stencil material, which allows it to be peeled off the backing and then applied to the surface to be painted. | ||

| + | |||

| + | [[Image:stencil-cut-4.jpg|300px]] | ||

| + | |||

| + | Pull the transfer tape off, leaving the stencil in place. | ||

| + | |||

| + | [[Image:stencil-cut-5.jpg|300px]] | ||

| + | |||

| + | At this point the part can be painted. Once the stencil is removed, the finished part is ready for installation. | ||

| + | |||

| + | [[Image:stencil-cut-6.jpg|300px]] | ||

Revision as of 21:03, 5 June 2015

Contents

Tools

Specialty Tools

- Pop Bumper Drilling Template: For use when drilling the playfield for Williams-style pop bumpers. Instructions for use here.

- Dupont KF2510 Crimper: Usually priced under $20 on ebay, this connector crimper works incredibly well. Used with 100 mil spaced connectors, standard pinball molex connectors, and spade terminals. It has three different sizes for different connectors. The trick is to start the crimp so that the ratchet holds the connector in its teeth. Slip the wire in to the terminal, and then finish crushing the crimp. The crimps are nice and tight and hold the wires very securely.

Metalworking Tools

- A few different colored sharpies for marking cuts and bends

- 4 1/2" angle grinder for cutting and grinding

- Flap disc grinding pads of multiple grits

- Metal cutting blades for a grinder

- Safety glasses and gloves

- A bunch of different size C-clamps - at least one large and two big enough to clamp large items

- A Square

- Measuring tape

- Different sized ballpein hammers

- Drill bits for steel

- Center punch

- Blow Torch - MAP Gas works best, Propane as a second choice

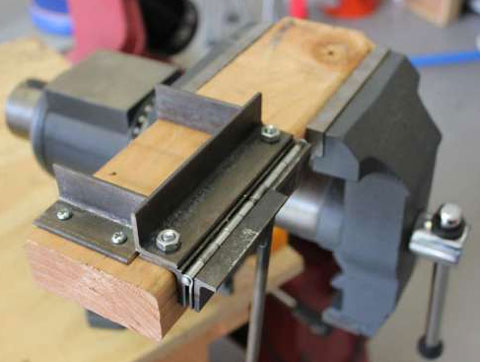

A Metal Brake is useful for bending sheet steel to make brackets.

The above example is available from Harbor Freight.

If space is at a premium, there are smaller tabletop versions as well.

If cost is an issue, you can make your own from common hardware store parts.

Woodworking Tools

Beyond the standard hand tools needed to create a machine from scratch, here are some additional tools:

A Hand Router for creating insert and device holes in the playfield.

A Table Jigsaw for cutting playfield plastics, or plexi for your initial whitewood inserts.

A Hand Sander to level the playfield. You should also have sand paper in various grits ranging from 180 up to 320, plus finer grits for final polishing.

Forstner bits for drilling clean holes. Easier than using the router.

Cabinet Tools

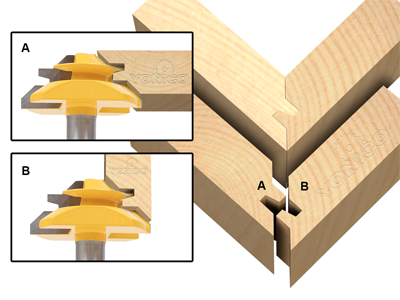

For cabinet building, a table router with Locking Mitre bits.

It is a bit that creates a locking edge between cabinet corners.

Advanced Tools

Although not strictly needed for hobbyists, the following are nice-to-have if you have some deep pockets, and they make whitewood production much faster and far more consistent. Rather than purchasing these, the best option is to find a local Maker Space that has the equipment available for rent or through a monthly membership.

CNC

A large-format CNC machine can take drawings from AutoCAD or Inkscape to cut a playfield exactly to the design, which will be much more accurate than one done by hand with a router.

Some reasonably-priced options include:

For smaller parts, there are much cheaper alternatives:

- Shapeoko uses a standard hand router, like a Dremel, as the cutting tool, and is priced under $1K.

Laser Cutters

Using a laser cutter on plastics means fast prototyping of playfield plastics, and most cutters will also do engraving for interesting effects. Really high powered units will cut wood as well.

Some examples include Epilog and Universal.

A lower cost option is the Full Spectrum Laser.

Materials

A rundown of the various materials needed to produce a whitewood.

Plywood

Commercial pinball machines use a specially sourced type of plywood that is not available from big box stores and generally not even specialty wood suppliers.

The thickness of a raw playfield is 17/32", which is then sanded on top with inserts installed to a finished size of 1/2". Each side is a full face of hard Maple with five plys in-between, not a thin veneer to allow for this sanding. The following photo illustrates the full seven plys:

The type of plywood available at a big box store will have a thin ply on both sides, generally of softer Baltic Birch, and will not have the surface area to allow a full 1/32" sanding to level the surface and inserts together.

For hobbyists, the best option is Cabinet Grade plywood, preferably from a lumber yard, with a minimum of seven plys but a preference for nine - the more plys, the more stable and flat. This type of plywood will have a thicker top and bottom ply suitable for sanding. It will generally be the softer birch but for one-off games, it should prove acceptable.

Another affordable option for whitewoods is Medium Density Fibreboard. Typically sold as MDF, it is also available in large quantities. The drawback for MDF is that it has poor flexibility and does not allow for easy removal and re-installation of screwed in parts. It is also a very heavy material since it is so dense. It is highly recommended to avoid using MDF for playfields.

Sheetmetal

For ramps, ball guides and various other uses.

Sheet Steel at McMaster-Carr.

Sheet Steel including stainless at Grainger.

Inserts

For a whitewood, the easiest option is to use thin plexiglass for inserts as it is readily available and fairly easy to cut to size with a table jigsaw. This allows for skipping the final sanding stage if using 1/2" plywood instead of 17/32".

Real pinball inserts are available in various sizes and colors from a number of suppliers including Pinball Resource and Marco Specialities.

Some examples of the inserts available:

5/8″ round White opaque #PI-58RW

1-1/2″ triangle Green #PI-112TGT

Rollover star button housing red 3A-7537 #C-901

Standard depth of inserts are 1/4" and they are designed to be sanded flat after installation - there will be a number cast into the top of the part and the top edge will be slightly raised around the radius by approximately 1/32". Thus, when creating insert holes, you must drill slightly less than 1/4" deep to allow for the sanding.

Off the Shelf Parts

Thankfully there are a number of standard devices that appear on modern machines that can be used on custom games, saving the garage maker a lot of time and effort by providing ready-made parts that don't need to be made from scratch.

Ball Trough

See the Ball Trough subpage for details.

Slingshots

See the Slingshots subpage for details.

Drop Targets

See the Drop Targets subpage for details.

Kickback

See the Kickback subpage for details.

VUK

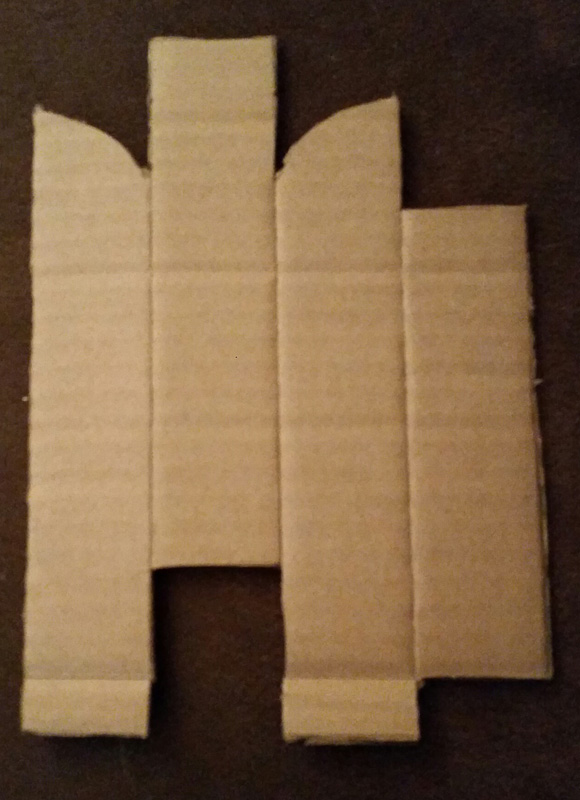

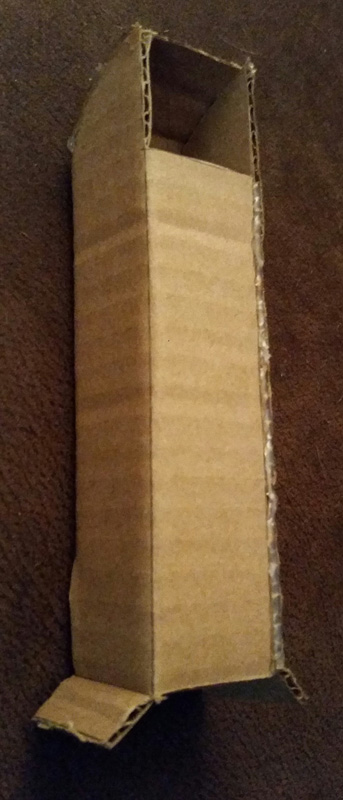

Also known as "Vertical Up-kicker", this is a scoop with a vertically mounted coil under the playfield with a post that kicks the ball vertically, typically through a scoop to bring a ball from one playfield to a higher one. Scoop heights can vary, so there's really no stock part that will work in all applications. Below you can see a VUK scoop made from cardboard, first cut out as a flat sheet, then folded up and glued along the edges (similar to bending sheet metal and tacking the gaps).

Hangers

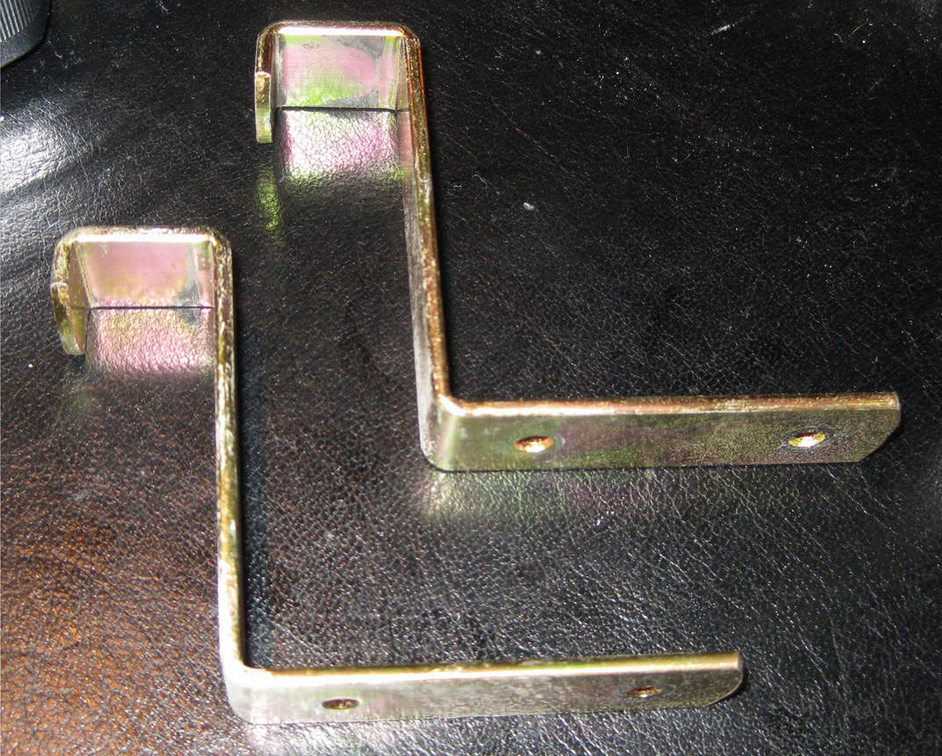

Hangers (sometimes spelled "hangars") are the brackets at the bottom of the playfield that attach to the lockdown bar mechanism to hold the playfield up. Every manufacturer seems to have slightly different styles. Early Williams used a Z-shaped bracket that installed from underneath the playfield.

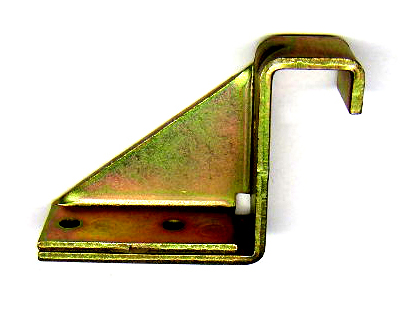

The currently available off-the-shelf bracket is the Stern/Sega bracket that has a gusset shape, and are mounted above the playfield rather than below.

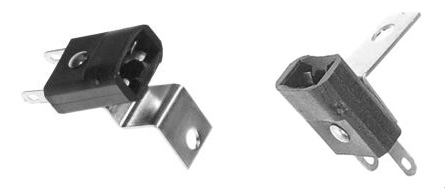

Switch Types

There are a number of options when selecting switches, all of which have been used in pinball machines over the years.

A Leaf switch consists of two metal blades held together in a contact assembly, with one of the blades generally being longer than the other. In a normally-open leaf switch, the longer blade is pushed toward the shorter blade to close the circuit. On a modern pinball machine, only normally-open switches are used.

A Microswitch is a small enclosed switch that has a sheet metal blade or wire actuator to operate the switch. The actuator is not electrically connected to the switch contacts, so it can be used in situations where directly moving one of the switch leaves would be dangerous. The blade or wire actuator can be bent into a convenient shape for the game requirements

Microswitches with wire actuators are used for playfield roll-overs. The wire is bent to stick up through a slot in the playfield. When the ball rolls over the wire, it pushes down on the wire which operates the switch. Ones with blade actuators are used for detecting a ball passing through a gate. As the ball moves the wire gate, one end of the wire swivels down to press the blade which operates the switch.

Optical switches use an infra-red light emitting diode (LED) to activate a photo transistor. There are three variations that are useful in pinball machines:

- Slot-Type: A slot-type optical switch has the LED and the photo transistor mounted in the legs of a "U" shaped plastic. The light emitting diode is always on, and a "blade" that moves in and out of the slot interrupts the beam turning the photo transistor on and off.

- Reflective: An optical switch that has the LED and the photo transistor mounted side-by-side and facing outward. When a reflective surface comes near the switch, the beam from the LED reflects back to the photo transistor. Typical range for this type of switch is 3-6 millimeters or 1/8" to 1/4".

- Separates: An optical switch that has the LED and photo transistors in separate packages. The light emitting diode is always on, and an object moving between the LED and the photo transistor interrupts the beam turning the photo transistor on and off. The range for this type of switch can be up to 30 centimeters or 12".

Proximity switches may be inductive, ultrasonic, capacitive, or optical. A proximity switch detects the presence or absence of something within a certain proximity (or range) of the switch.

Inductive proximity switches work in two different ways. The Active type, an oscillator generates an electromagnetic field. When an electrically or magnetically conductive object enters the field of the oscillator, its frequency is altered, and the output switches. This type of switch can only be used when oscillator field will not sense too large an area. The Passive type uses a coil with an iron core or a semiconductor in a magnetic field (Hall effect sensor). A moving, magnetically conductive object disturbs the magnetic field and generates an electric current. This type of switch is not sensitive enough to detect a pinball reliably. It is used for detecting regular movement like gear wheel teeth rotating past, or with a magnet in a keyboard switch.

Capacitive proximity switches work in two different ways. The Passive type has a sensor that consists of two concentrically mounted electrodes (which are the electrodes of an opened capacitor). When an object approaches the sensor, the electrostatic field is changed. (It changes in opposite directions for conductive and non-conductive materials.) This change is detected by the switch. The Active type capacitive switches operate by generating a radio frequency. As an object approaches, the impedance seen by the radio frequency changes. This influence is measured within the circuitry and compared with the reference point set by the sensitivity adjustment.

The key factor for a switch is that it electrically completes a circuit, so they can consist of any two conductive objects being connected - so, even the pinball itself can be used as a switch if it connect two wires together!

Playfield Parts

The best source of parts like switch targets, pop bumpers, posts and other miscellaneous bits is from parts machines - picking up a used machine with a worn playfield and just cleaning up those parts will be ten times cheaper than buying all new parts.

However, given the increasing value of even older solid-state machines, finding games to part out is becoming increasingly difficult, so the only option may be purchasing new.

Once a preliminary design is complete, the next step is to create an initial prototype, known in the industry as a Whitewood.

Whitewood

The origin of the term whitewood is related to the material of the playfield, which is traditionally White Maple. The first iteration of a game will not have any artwork or lighting as the purpose is to test the layout, flipper shots and the overall feel of the design to confirm it plays as expected.

The second iteration of the whitewood - generally a different playfield rather than the existing one re-cut - will include inserts, lighting and any ramps or playfield devices needed for the complete game. This version of the prototype is used to create the first iteration of the ruleset and special effects.

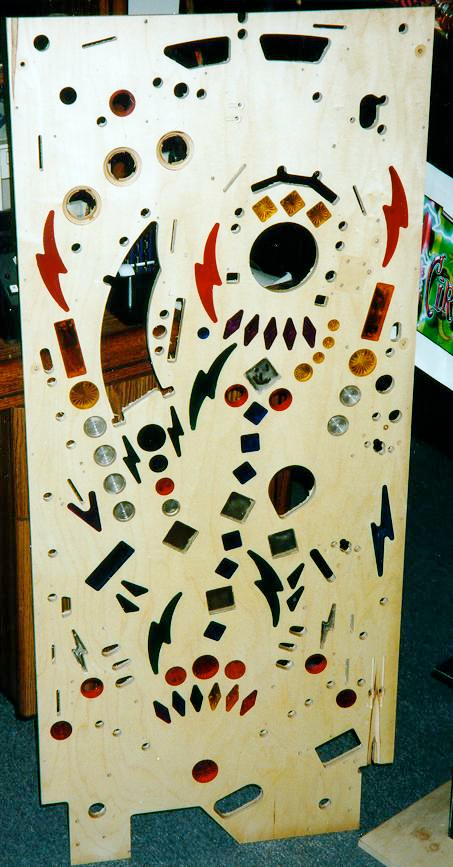

Here is an unpopulated whitewood for Cirqus Voltaire, which is a later iteration that does have inserts for lighting, but not yet having artwork.

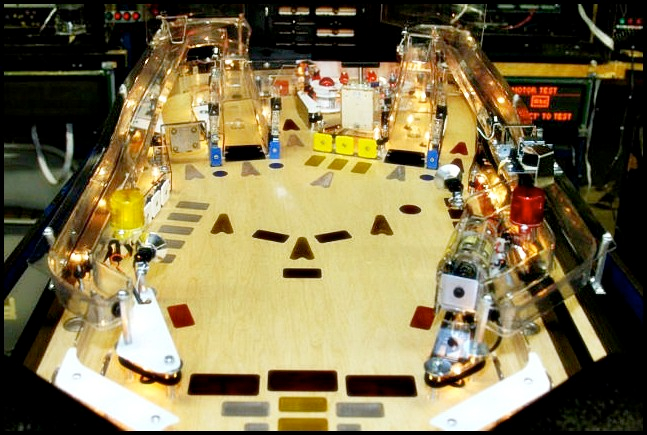

Here is a populated whitewood for AC/DC, which does not have the later sub-playfield so is much earlier in the design process.

Typically a playfield is made of 9-ply birch plywood, 17/32" thick with the additional 1/32" allowing for the inserts to be sanded flush. A number of European manufacturers used plastic playfields, and some domestic companies experimented with them in the 1970's, but the vast majority use plywood.

Standard Playfield Sizes

see Playfield Sizes

Foam Core

When creating an initial whitewood to test shots, install the lower third (flippers, slingshots) and side rails, but use Foam Core for your ramps and any upper playfield stuff. It is easy to cut and form with hot glue, quickly and cleanly. It is also strong enough to endure test playing without breaking.

Use 1/4" to 1/8" for ramp bottoms, and hot glue thinner posterboard on the sides. You can also use posterboard for the transitions between the playfield and the ramps. Trace the shape of the ramp on the foam core, cut it out, then glue on thinner sides.

Foam core can also be used for stand ups, pop bumpers and other devices to test other shots. Either stack it or stand it up and glue it together. Use hot glue for everything - easy to use, dries quickly, holds strong, and you can rip it apart to change things as needed.

When complete, the game should be basically playable in terms of playfield and ramp shots, and if the game plays okay with foam core, it will play even better in plastic and metal.

An alternate to foam core (which can be pricey at $7 for a 2' x 3' sheet), is cardboard. It is a material that is readily available in multiple thicknesses and footprint sizes, often obtainable for free since it's such a highly recycled material. It can be bent at angles and remain stiff in fluted versions, or bent in a curve by squishing the flutes down, very similarly to sheet metal. Since cardboard has no foam inside, it can often be stiffer and closer to a harder material like plastic. It is as easily cut with an x-acto blade or scissors.

Cutting

(Sourced from a tutorial by Josh Kugler) [1]

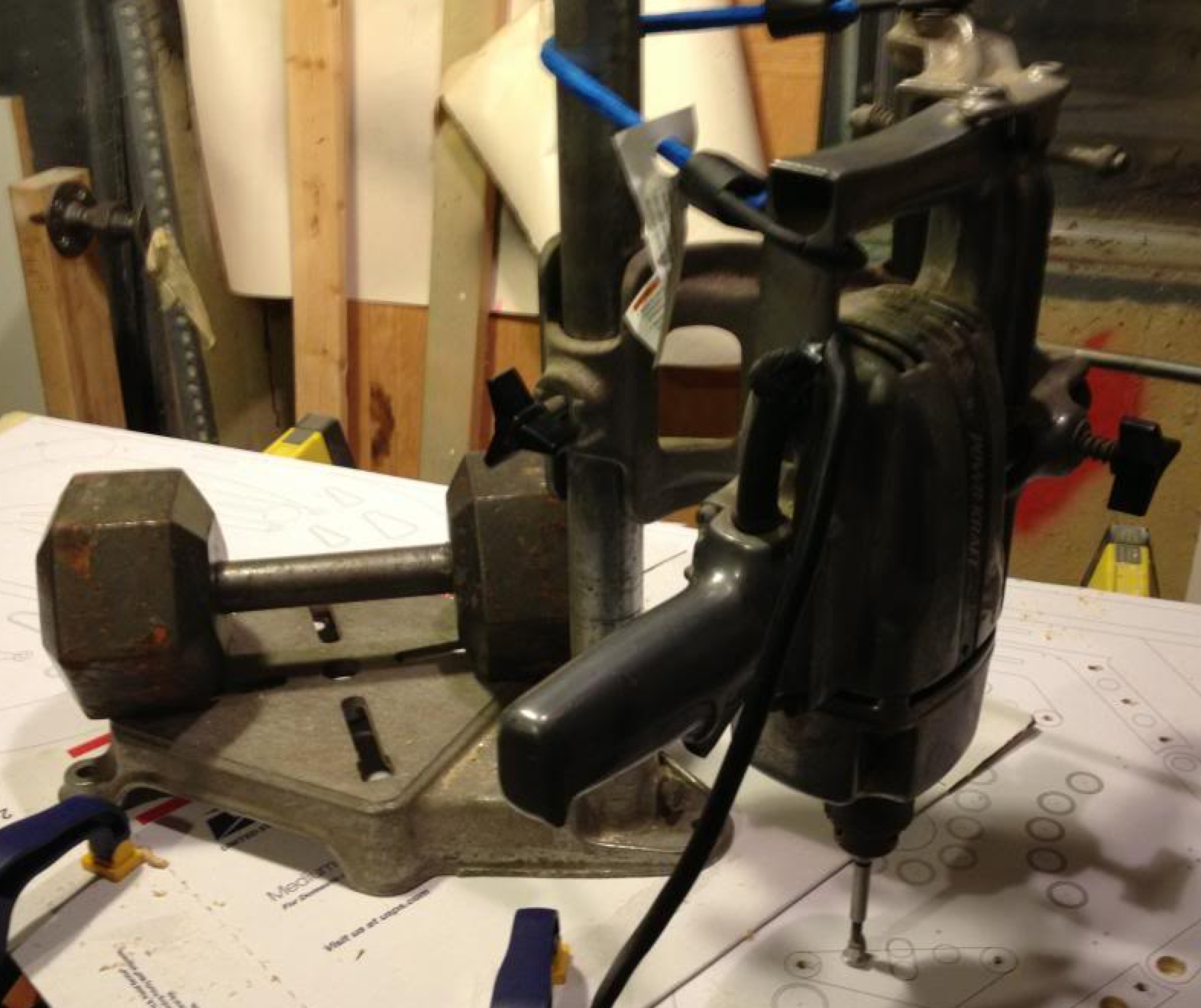

Before proceeding with any cutting, a completed playfield drawing is needed, to be used as a template. For details on that portion of the process, visit the Design section of the wiki. One tip that will help later is to add centering lines to all the drilled insert circles to aid in proper placement.

Once complete, take the file to a FedexOffice or similar Printing House and have it printed full size. Use 3M Spray adhesive to glue the print to your playfield surface. This print acts as your drilling and cutting template.

Use two Forstner bits for each insert. The first is the wider opening that is the same size as the insert, drilled to the appropriate depth of the insert which is typically 1/4". The second bit is 1/16" smaller can then be used to drill the through hole. This leaves a 1/32" lip for the insert to sit on.

Since the Forstner bit has a centering point there is a natural centering hole for the second bit, making it easier to get it lined up right. The cleanest technique is to drill just short of going through, and then complete the hole from the other side using a standard cordless drill.

Don’t do the three steps in order per hole, but the first step for a bunch of holes, then the second and third.

For creating a non-circular insert, use a router with a template and Bushing guide - a router bit with a small roller bearing on it runs along your guide, while the cutting head runs in the playfield to cut the hole to the size of the template. Creating the template is the hard part, but once you have that, it is relatively easy to route multiple holes for the inserts. This is a three step process similar to the circular inserts.

As with the circular inserts, first create the wider opening. This is done by clamping the template to the playfield and then routing the wider opening using the bearing bit.

Drill a couple of holes in the center of the insert so there is less to route. This is also helpful when doing the second step, of cutting out the inner opening, that is slightly smaller then the insert opening, since the router bit can start in one of the holes and not have to be plunged into the wood.

A 3/16" bit and a 5/16" bushing/guide offers the best results, which gives a lip of 1/16", a little bigger then for the circular inserts. This second routing can be done without a template, since the insert opening itself can act as the template.

Cabinet

Made from 3/4" plywood, mitre-jointed at the corners. Some of the considerations when designing or building a pinball cabinet include:

- Switch locations

- Side rails

- Lockdown bar mechanism

- Plunger height

- Coindoor size

- Leg mounting brackets

- Speaker bezel

There are typically two cabinet styles, Standard body and Wide body.

Cabinet Parts

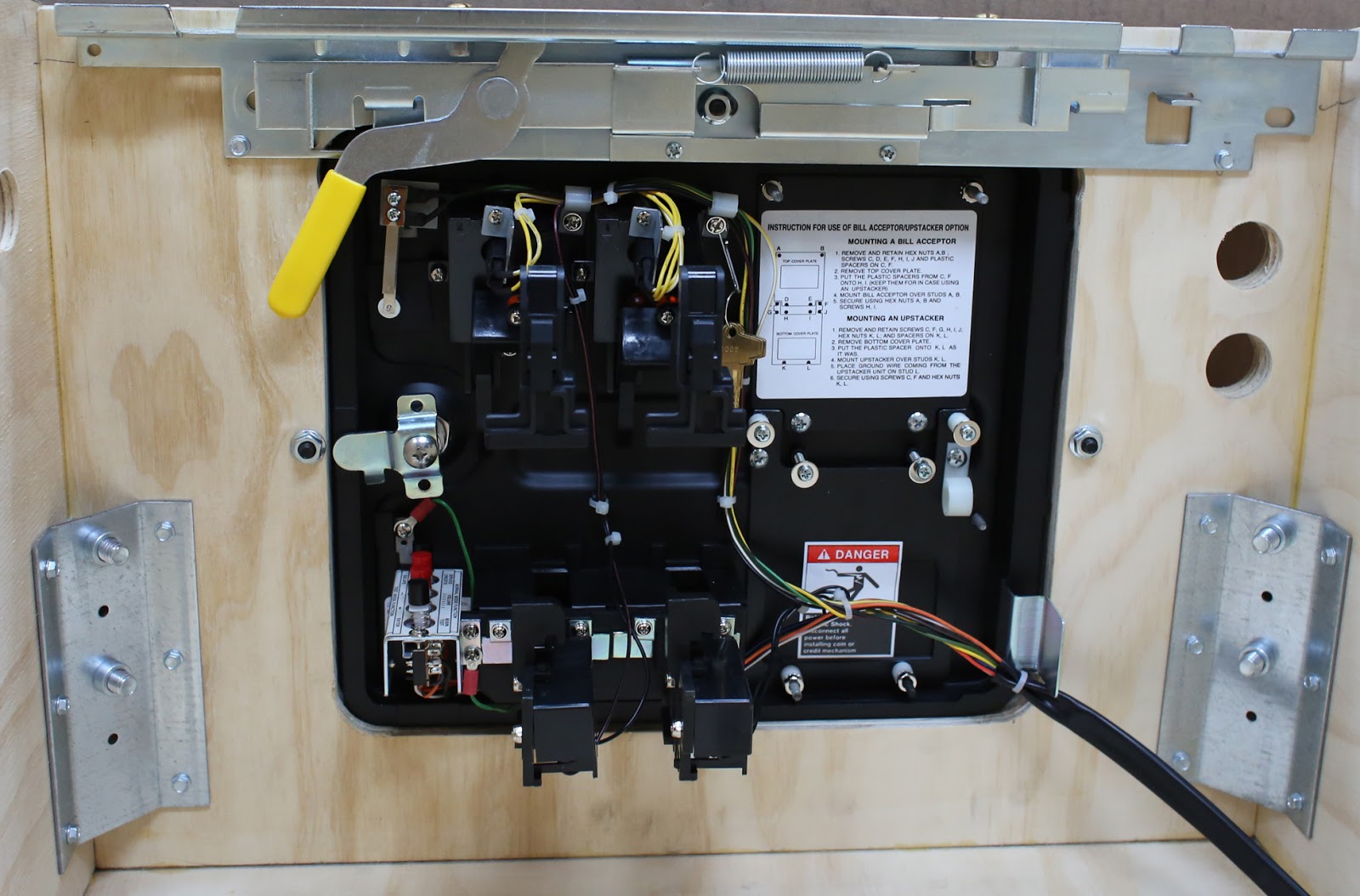

If building a Williams style standard cabinet, VirtuaPin offers a Ultimate Cab-Builder's Kit that has all the cabinet-specific parts in one handy kit.

When cutting your cabinet for the coin door, keep in mind it is installed with four bolts centered on the bottom, sides and top, and that the top hole goes through the lockdown bracket. So both need to line up.

Electronics

Once the physical playfield is constructed, wiring it all together and adding a way to control the devices will be required. There are three basic options - use existing pinball boards, build custom control boards or purchase off-the-shelf units.

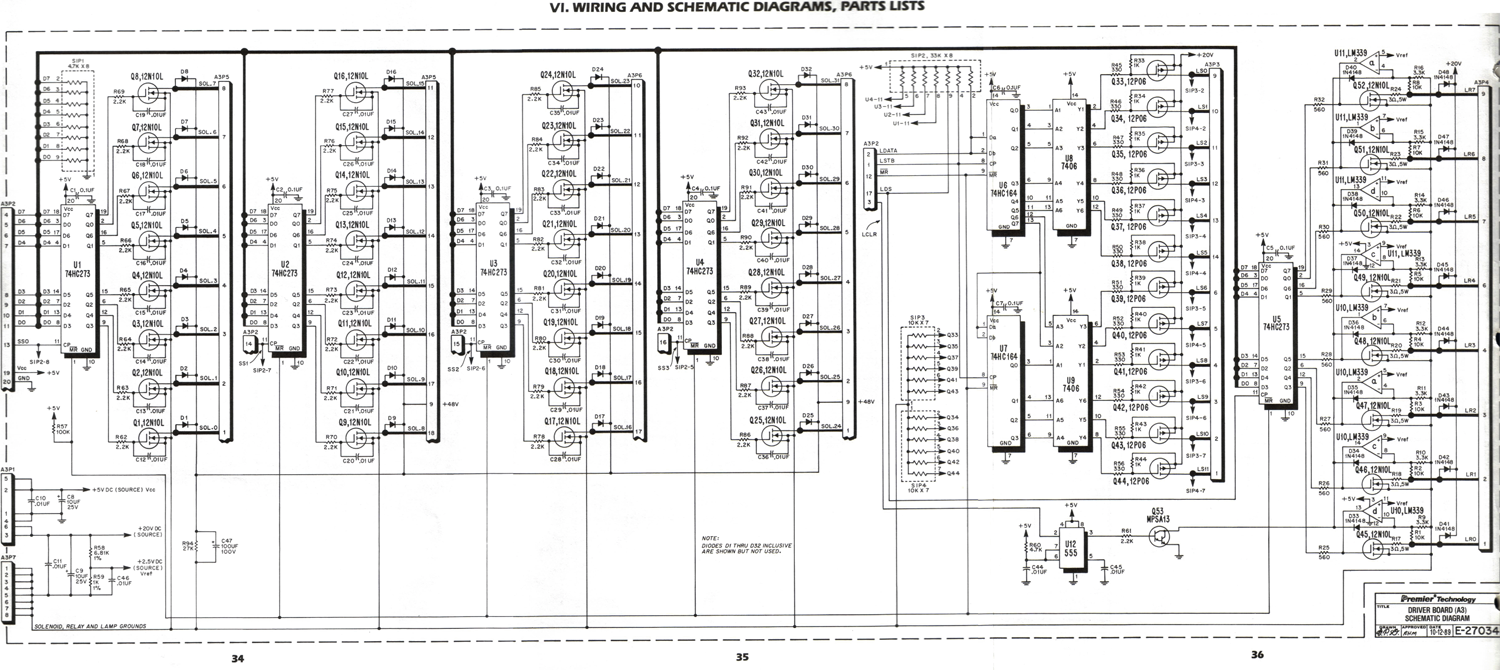

Existing Boards

A popular option is using boards from existing machines and replacing the main controller. For example, the Gottlieb System 3 driver board uses modern MOSFET drivers, supports 32 coils and a 8x10 lamp matrix, and is available for $100 from Pinball Resource.

Another well documented system is the original Bally system.

Custom Boards

- Pinheck is a system designed by Ben Heck for use in America's Most Haunted and is not currently available in kit form, but you can download the design and have it printed yourself for use in your own games.

- System Shock is a work-in-progress and currently only the driver board is available for download.

Off-the-Shelf Boards

- P-ROC (Pinball - Remote Operations Controller) is a well-supported generic platform that is in use by many custom games. It has a dedicated forum.

- FAST Pinball is the new kid on the block that will be bringing out a controller in 2015.

- milliSoft Offers an all-in-one board.

Controller PCs

Most off-the-shelf systems require an external PC with USB to provide the signals to control the solenoids and lamps. Currently these small ARM-based boards are the best candidates as they are more powerful than the Raspberry Pi or Arduino boards:

- O-DROID : Quad-core CPU, dual-core GPU, 1GB DDR3 RAM, Gigabit Ethernet , 4x USB2.0 ports.

- Beaglebone Black: AM335x 1GHz ARM® Cortex-A8, 512MB DDR3 RAM, 4GB 8-bit eMMC on-board flash storage

- CubieTruck: ARM® Cortex™-A7 Dual-Core, 2GB DDR3, HDMI & VGA 1080P display output, 10M/100M/1G Ethernet, Wifi + BT, SATA 2.0 , NAND+MicroSD or TSD+ MicroSD or 2*MicroSD

Coil Sizes

When choosing coils, it is important to understand how coil sizing works.

For example, decoding the Williams part number AL-23-550 has three parts - the prefix AL means the coil has base wire lugs on the left and middle of the coil's base, while 23 is 23 gauge wire and 500 is the number of turns of wire. The more turns, the weaker the coil.

For more details on coils, check out the Pinball Medic coil chart.

Power Supplies

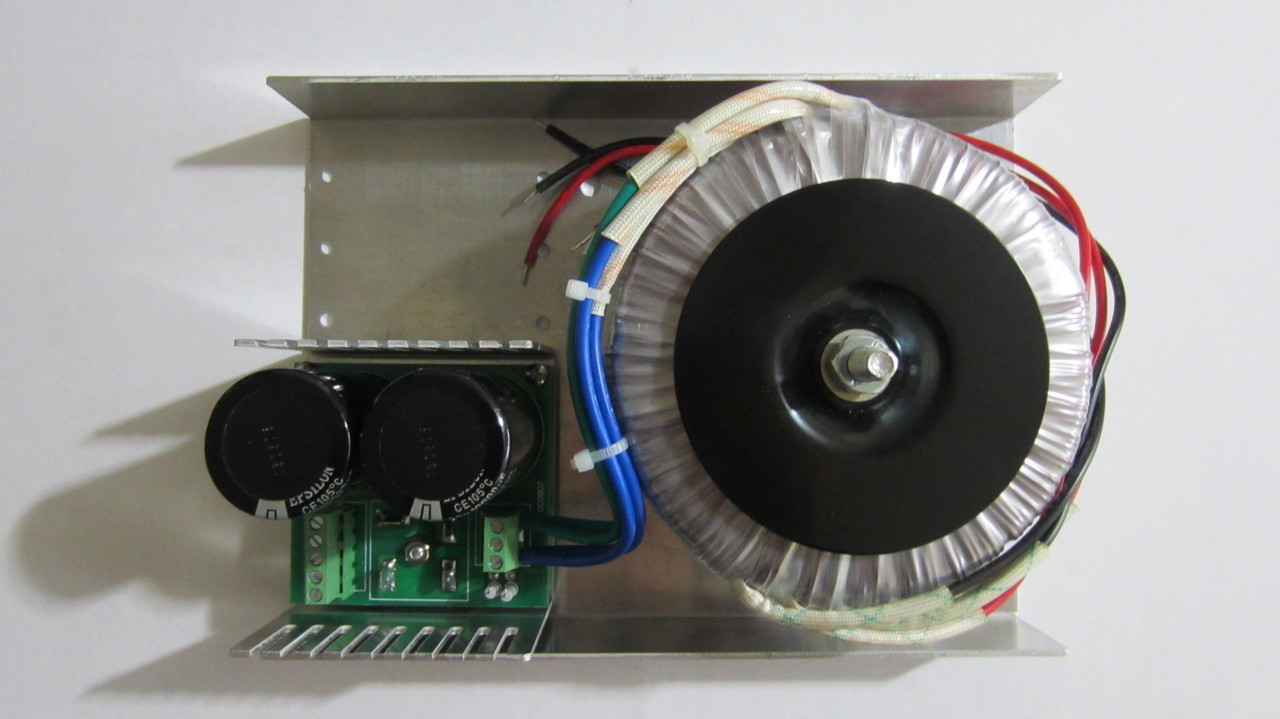

There are a couple of options when it comes to power.

- Commercial Pinball Transformer / Power Supply: Most dedicated pinball transformers will provide various power level taps like 6.3V for the GI and CPU, 24V for basic coils and 50V for flippers and other high-current coils. You'll need the comparable power supply board to convert the AC voltages to DC, or create the power supply yourself.

- AnTek: The model PS-4N70R5R12 provides high current 70V as well as 1A 5V/12V feeds to run the CPU and lights.

- TDK-Lamda: Available from Digikey. Model LS150-36 is a 36V switching supply, suitable for most standard coils but may not be enough for flippers or VUKs.

- Meanwell: The SE-600-48 is a 48V 12A supply which can be dialed up to 50v. There are also lower amperage 48V models such as the Meanwell NES-350-48 which provides 7A. Meanwell is a highly respected brand that make very good power supplies.

- eBay: Search for CNC Power Supplies. These will often be 48V high current switching supplies designed for stepper motors and will provide enough power for coils so long as the maximum current isn't exceeded.

It is recommended to get at least a 3A supply. The quality, especially from China, is not always guaranteed. Be sure to choose one with a case that has adequate venting to prevent shorts if any metal items are dropped on the circuitry. Power supplies with fans are recommended. They typically won't turn on unless they get hot enough (Coils pulling excessive current, hot ambient temperature).

Computer power supplies are fine for CPU and some lighting, but won't provide enough current for solenoids.

As a side note: If using a standard PC as the CPU for the machine, there is a useful board for controlling PC power supplies from the external high-current supply.

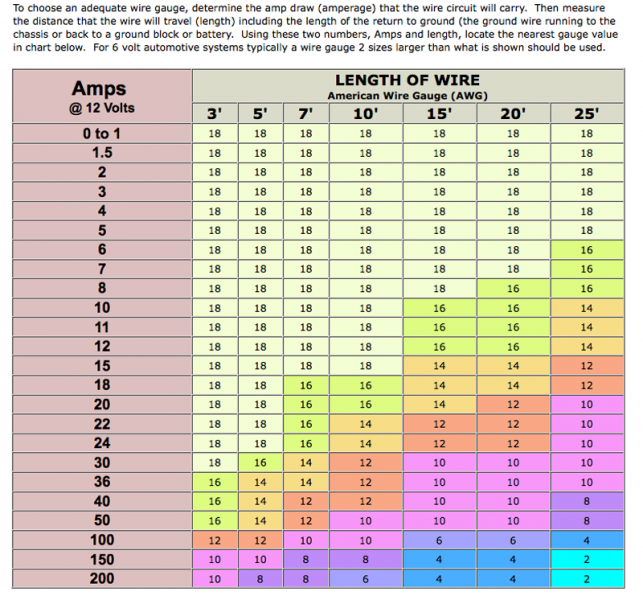

Wiring

Most pinball machines have wire harnesses of some type. As high-current devices, solenoids typically need a minimum of 18AWG wire. Wiring for lighting and switches can be much thinner since it's pulling less current, particularly if using LEDs, so 20-22AWG wiring is acceptable for low-current uses.

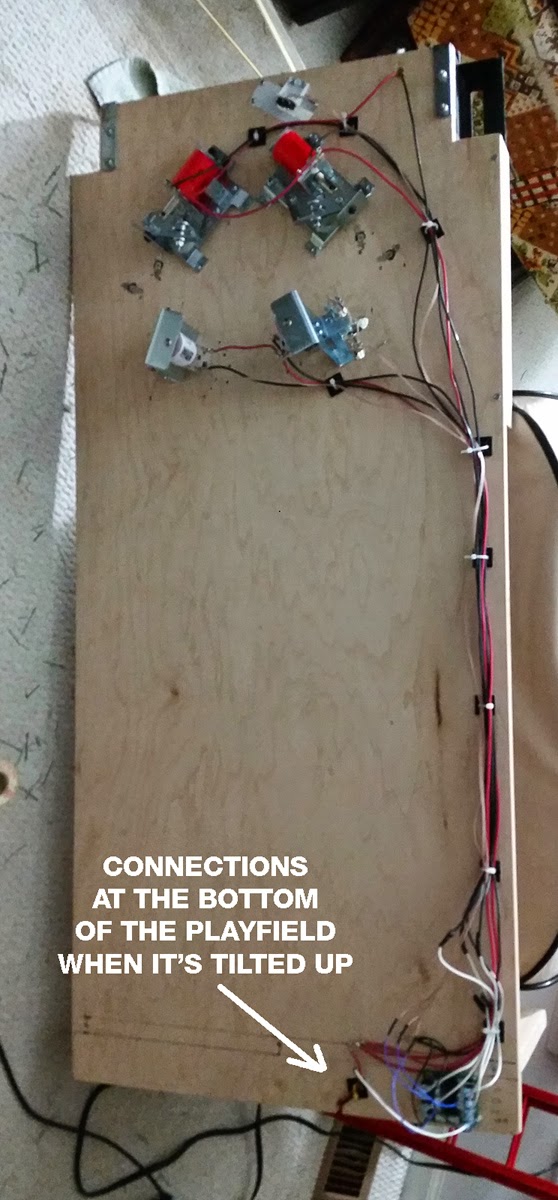

Wire Management

Because prototyping (or one-off) projects don't have pre-determined wire lengths and quantities, how wire is routed will change many times before the game is complete. It is highly recommended to use tie mount bases (with adhesive) versus clips that are permanently screwed into the playfield. That way they can be moved around as needed.

It is also recommended to use re-usable tie-wraps, which allow repeated opening and closing as needed.

Here is an example of a prototype playfield using these types of wire holders:

Wiring Harness

Once the final wiring layout is complete, paper templates of the playfield layout on thick cardboard or wood paneling can be used to make a Wiring Pinboard, similar to the boards that the manufacturers use to make their Wiring Harnesses. Place nails in appropriate spots and run wires as needed, with tie-wraps.

Color Coding

To aid in troubleshooting and wire layout, pinball companies use color-coded wire, where it has one color as the main jacket and a second color as a smaller stripe, allowing for many color combinations. For instance, Williams used yellow and white wire for lamps.

Getting a full stock color-coded wire can be very expensive, but the folks at Mission Pinball came up with a cheaper alternative method of properly color-coding wire using cheap PVC piping.

Start with purchasing single-color wire in 50' - 100' spools. Get 18 and 20AWG spools for each type of wiring. The more base colors to start, the better.

Next, get some oil-based markers, which can be found at local hobby stores. One notable brand is Sharpie, and they should be labeled specifically as oil-based paint markers - water-based will scratch or wipe off easily. They will be more expensive but are the only type that work correctly.

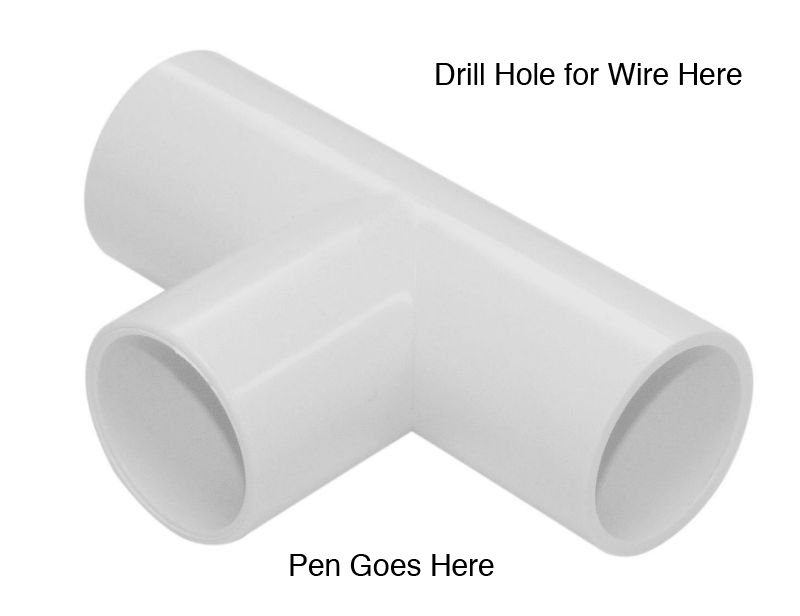

Although Mission used a wood block to hold the markers, using a PVC T joint and drilling a hole through it in the center allows the placement of the paint marker in the T portion of the joint and pressing down on the wire as it passes through works very well.

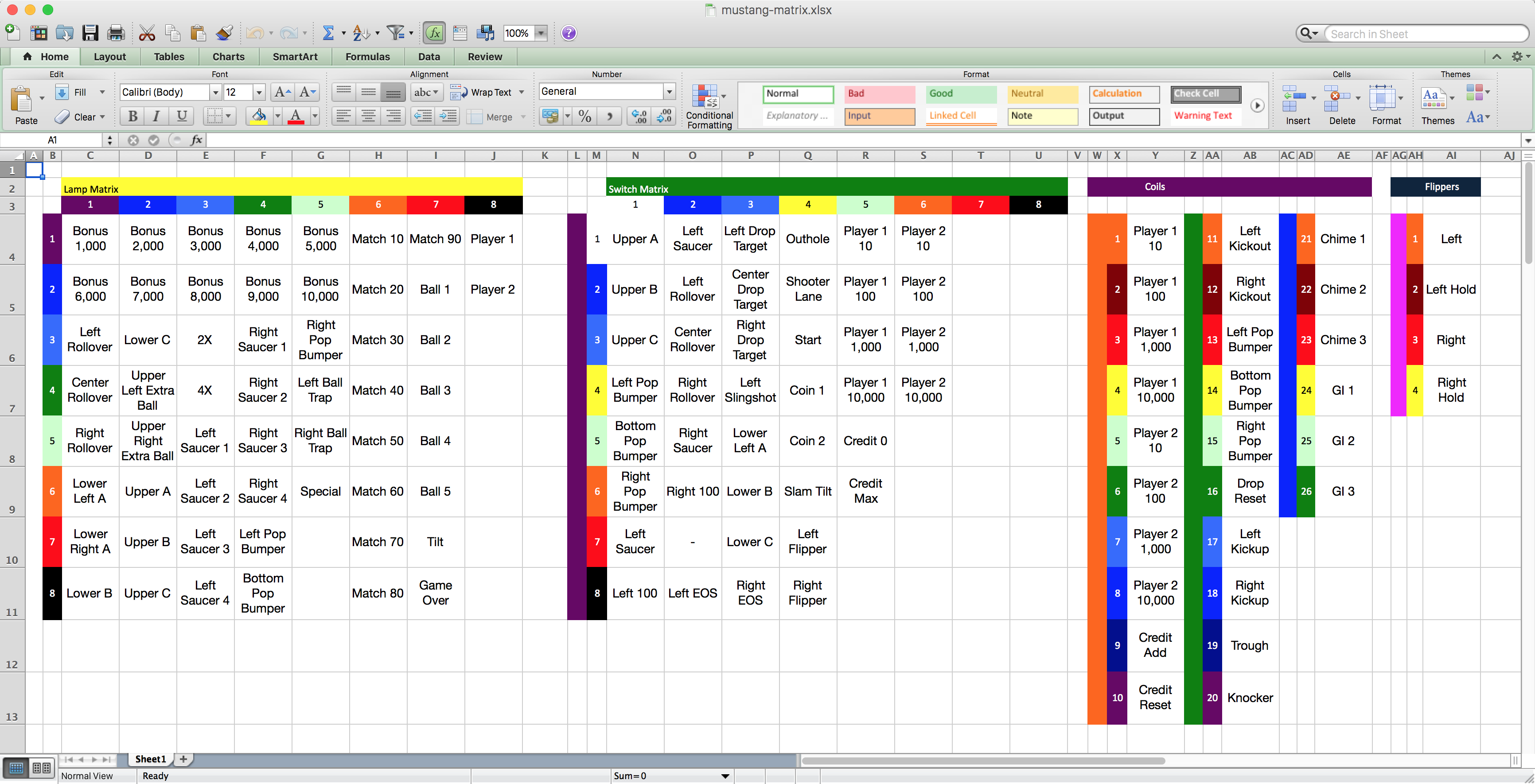

Matrix Color Coding

Where color-coding is particularly important is in Switch and Lamp Matrix layouts. Plan ahead and design your color scheme before starting the construction of the game in a spreadsheet.

Below is an example of a color layout for a custom game. This document can be referenced during construction to make sure the right wire is going to the right switch, lamp or coil, avoiding troublesome issues later during the testing phase.

Displays

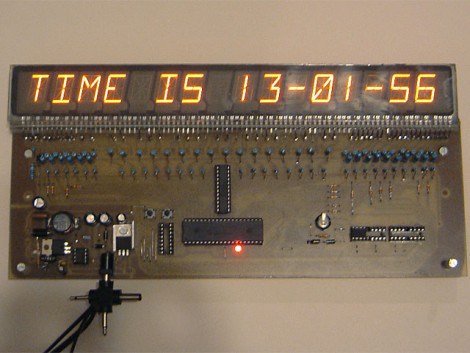

Numeric / Alphanumeric

Numeric or Alphanumeric score displays are sometimes chosen even today because of the ease of programming - they display simple scores or lines of text only, so no complicated graphics need to be designed or coded. That means more time to concentrate on gameplay versus interfacing with the player.

Gas Plasma

The first commercial solid-state displays in common usage were Gas Plasma displays. They use high voltage to cause a noble gas like neon to glow. Shaping the conductive layers into digits allows the display of multiple numbers or letters.

These types of displays are not only dangerous, due to the high voltages required, they are prone to burn-out or out-gassing, and have been obsolete for many years. Unless re-theming an older game and wanting to re-use existing parts, or trying to maintain a retro look, it is suggested to use LED replacements.

LED Displays

The pinball after-market has produced a number of excellent plug-and-play LED display replacements.

- X-PIN has 6- and 7-segment displays as well as alphanumerics.

- Pinscore has retrofit kits for older machines.

- PinLED in Europe has a variety of options available.

Additionally, there are many generic LED displays to choose from:

- Adafruit offers a number of LED segment displays with instructions on programming them with various microcontrollers.

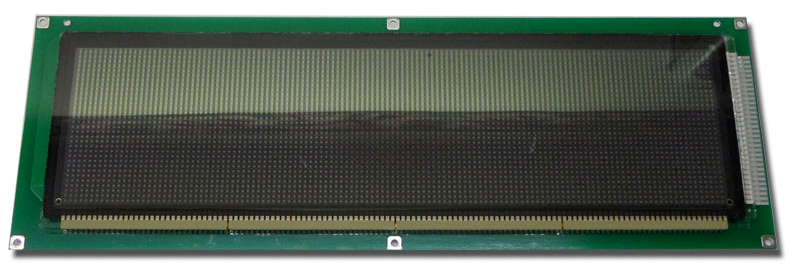

Dot Matrix

Modern games make use of either a gas plasma or LED Dox Matrix Display or DMD. They work on the same principle as the segment display except they use round pixels in a grid pattern - or matrix - to display game information.

The complexity with these displays is that the programmer must construct numbers or letters in a graphic format and then push that data to the display. Rather than program "display 300,000", they must use bitmap fonts and determine screen placement.

However, many programming frameworks currently available offer this functionality built in and are an excellent place to start learning about game graphics.

Other options for matrix displays include:

- Evil Mad Scientist offers the Peggy 2 DMD kit for exploring DMD programming.

- Adafruit has a variety of matrix boards with programming instructions included.

- Embedded Adventures has kits as well.

LCD Display

The trend for modern games is using LCD screens in place of DMDs or other older display technologies. Full color with high resolution, the results can be very attractive. However, at this level a game designer essentially becomes a videogame designer. A pinball maker has to wear many hats but it is the rare individual who can do both construction and handle graphics duties.

There is some discussion of the technical side of graphical displays on the pinballcontrollers Forum.

Lighting

Socket Styles

Most lighting is socketed either by a bayonet or wedge socket.

Bayonet is preferred since the bulb is more likely not to wiggle itself out from vibration during play and transport. While pinball started out with incandescent bulbs, most are moving towards LED for many reasons:

- Less power draw

- More color options

- Lasts longer which means replacing less often

- Less damaging. The constant heat/cool from incandescent bulbs are known to warp plastics and cause flaking on backglasses.

Bulb Types

The most common sizes are the #44/#47 Bayonet Base, the #555 Wedge Base, the #89 Bayonet and the #906 Wedge.

One drawback of LED's are that they don't have a ramp-up of brightness like incandescent bulbs, and sometimes they can be bright enough to hurt the eyes. The ramp-up effect can be emulated in software if the lamp controller has enough brightness levels, and diffusion-style bulbs help the brightness issue. They are best used as General Illumination.

Modern Stern games going forward use a Surface Mount LED board that are driven directly which eliminates the need for sockets altogether. The drawback to these are that the boards are directly soldered, so if there are issues, they can't be easily replaced. However, the long life of LEDs makes it unlikely for them to burn out at the rate incandescent lamps do.

For a custom game, a combination of Cointaker Premium Frosted or Ablaze 4-LED for GI and the FAST Pinball RGB LED Insert boards for inserts are a good choice.

Lit Flipper Buttons

Thanks to newer LED bulbs there is more flexibility to installation than ever before.

For lighting translucent flipper buttons, use a #44 bulb holder and some 44/47 Flex Super Bright lamps from Cointaker.

Screw the Socket under the flipper button and out of the way of the Flipper Button Leaf Switch. Position the head of the LED so it is shining slightly up. Don't let the LED head touch the Leaf Switch, or it may wear out the LED or break the LED's leads.

Custom Parts

Many hobbyists plan on producing games with game-specific features that aren't included in other machines, such as ramps or ball control devices, and thus will have to design and construct mechanisms from scratch. This generally involves metalworking, welding and other more advanced skills, but are not beyond the garage hobbyist.

Plastics

Slings are often the same shape since the posts are often in the same location (but they may not depending on your design). With that said, there will likely be many other plastics scattered on the playfield to:

- Hide mechanisms

- Improve aesthetics

- Prevent a launched ball from getting stuck in a crevice

While you can buy expensive laser cutters as shown above, or farm it out to a vendor, if you wish to produce your own plastics to save money (or as a first run prototype that's not cardboard), it's recommended to buy something easier to cut than acrylic, such as 1/16" PETG which can be purchased very cheaply from mcmaster. This can be cut fairly easily with strong scissors (or an x-acto if you're careful), and like acrylic it can be flame polished.

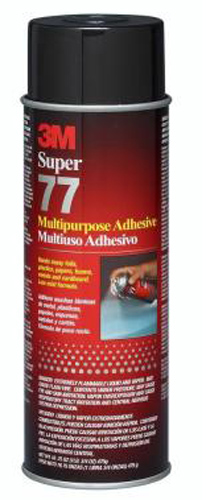

To create artwork, the best method I've found is to print it on photo paper, and then using a spray adhesive to attach it to the bottom of the plastic such as 3M's super 77 (try to find the 25% lower VOC verison). These products dry clear and will not yellow.

- PLEASE USE CAUTION WHEN USING THIS PRODUCT, IT IS HIGHLY VOLATILE. USE IN A WELL VENTILATED AREA!*

First you want to trace your plastic shape on the plastic. Leave the thin film on top, remove from the bottom where art is being applied. You'll want the artwork to be just slightly bigger than the plastic to ensure there are no gaps when you trim

Make sure you spray in light even coats on the backside of the plastic. Let it get tacky for 10-15 seconds. Then move your printed art (art side up) over, and turn the plastic over and apply the plastic onto the paper (this will make it easier to line it up)

This is what it will look like when it's first applied. Don't worry, the adhesive will turn clear as it dries

Once the adhesive has dried, you can safely drill the holes starting with a small bit, and working your way up to the hole size needed depending on your post size

Then you can trim off the excess paper by using the plastic as your guide. Trim slow and carefully as to not dig into the plastic with the knife and ruin your hard work

Here's an example of prototyped plastics installed on the slings

The white paper acts as a nice distiller to spread the light out, just like real plastics

3D Printing

(From Wolfmarsh's Pinside tutorial)

The big revolution in garage building is 3D printing.

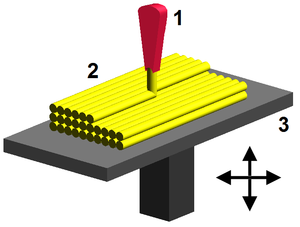

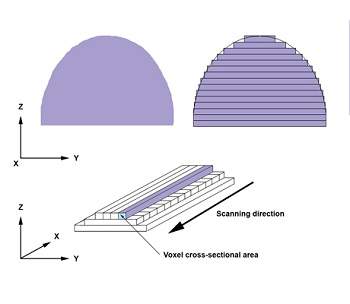

The most popular among home machines is Fused Deposition Modeling (FDM for short). FDM is where a thermoplastic filament is slightly melted, extruded through a small nozzle, and deposited in layers to build up the object. Most home printers use this method.

Here is an image that gives the general idea. One is the Extruder, two is the deposited Layers, and three is the Build platform.

A second method that is popular with the higher end machines, is Selective Laser Sintering (SLS). With SLS, a layer of powder is deposited on the build surface, then a laser melts specific areas together. The build surface lowers a fraction of a millimeter, and more powder is deposited. Repeat until the object is built. Here are a couple short videos that shows how SLS works:

https://www.youtube.com/watch?feature=player_embedded&v=sFpSxX0SzgY

https://www.youtube.com/watch?feature=player_embedded&v=-6ItiCbYFvI

Buying a Printer vs Using a Service

Most home printers will print using plastic filament and FDM. Services like Shapeways can afford higher end printers that offer higher resolution with SLS.

For most of what a garage builder will do, FDM and home printing will cover it. If a full color print or some very fine details are needed, like screw threads, the part can be ordered from Shapeways.

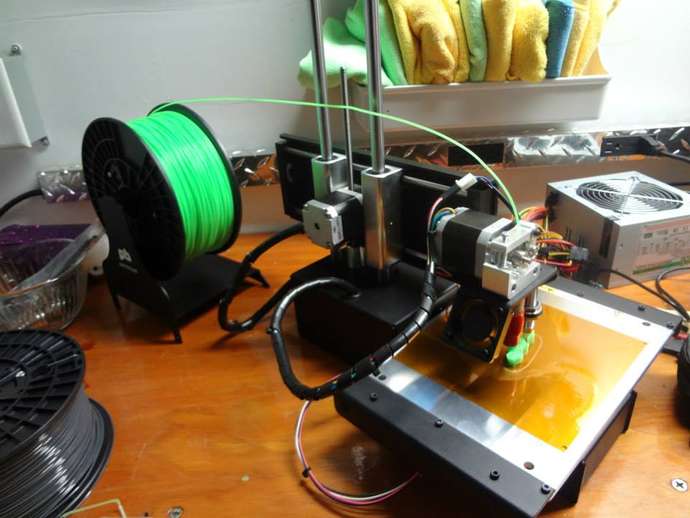

If planning to purchase a home printer, it is recommended to read the Make Guide to 3D printers. One option is the Printrbot Simple Metal Kit with a Heated Bed upgrade.

Generally with the lower cost kits, the only real sacrifice is speed and maximum build size.

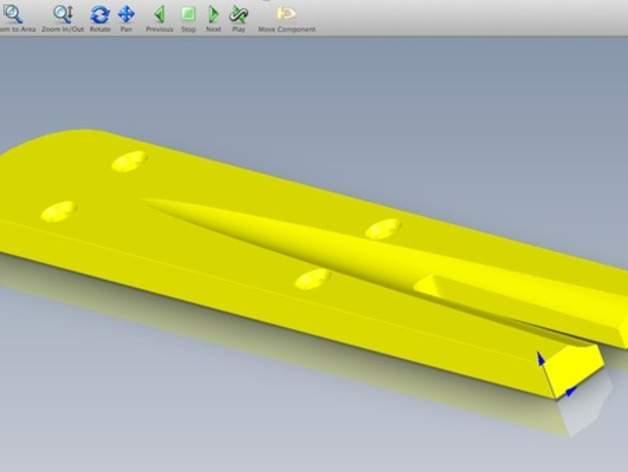

Printing an Object

The easiest way to get into 3D printing without having to create models is to download pre-made models. A great source for this is Thingiverse. Pinball parts are starting to appear on Thingiverse, so there is a small library already available.

For example, here is a shooter lane designed by Pinside contributor swinks:

Download an .STL file of the model to print. It contains the geometry for the object in a language the printing software can understand. Once you have the .STL file, you feed it to a Slicing program like Slic3r. A slicing program takes a 3D model and cuts it into the layers needed to feed to the 3D printer.

Here is a quick example of how it works. The model is on the left, and the sliced version on the right.

Once the object has been sliced, the program will generate a G-code file, which is the common language that CNC machines use.

A G-code file looks like this:

G1 X52.008 Y54.121 E2.04455 G1 X51.948 Y52.484 E2.13013 G1 X51.969 Y52.373 E2.13608 G1 X52.042 Y50.606 E2.22844 G1 X52.067 Y50.514 E2.23342 G1 X52.258 Y48.934 E2.31658 G1 X52.708 Y48.561 E2.34712 G1 X52.998 Y48.608 E2.36247 G1 X54.421 Y48.632 E2.43686 G1 X54.532 Y48.659 E2.44282

This example is a bunch of G1 commands that tell the machine to move to a specific X position, a specific Y position, and to Extrude a specific amount of filament. The G-code file gets loaded into the Printer control software, and slowly fed to the printer as it prints the object.

The Printrbot example above can be driven using a Raspberry PI, running a special image called OctoPi. It provides a web interface to the printer.

If everything worked as expected, at the end of the print process there is a real, complete object based on the models:

If things don't go well, it may end up as a bunch of trash plastic. It happens.

The key is to experiment and find shapes that work well, and to design shapes with the properties of the materials being used - if building brackets to hold coils, the resulting bracket should be thick enough to maintain its shape when the coil fires. The following is an example from America's Most Haunted.

Vacuum-Forming

(Sourced from a tutorial by Josh Kugler) [2]

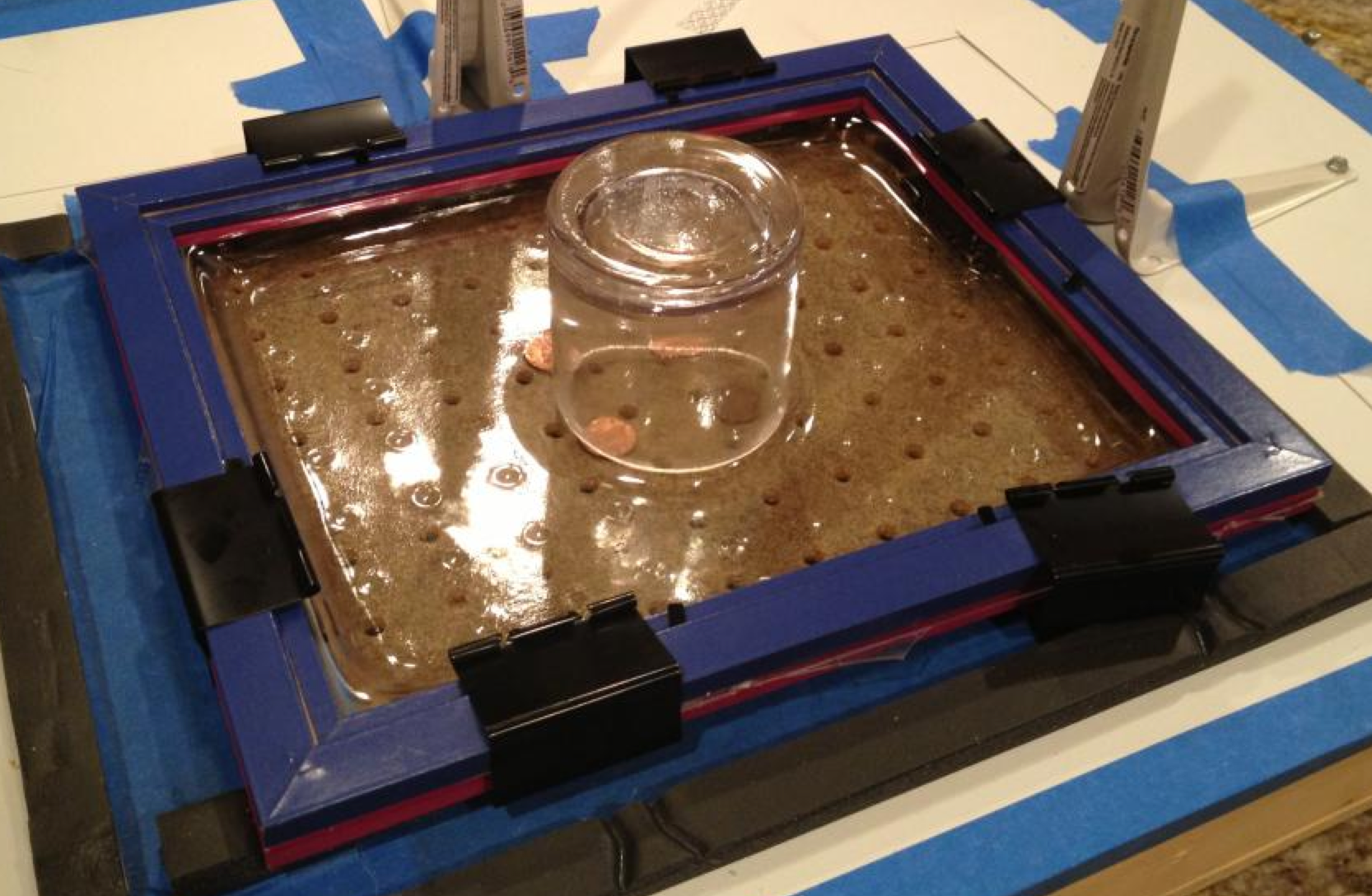

Doing simple vacuum-forming in your garage is straight-forward. The basic idea is to use a standard oven to heat up a sheet of plastic until it softens, then place it over a pre-made form, using a vacuum to pull the plastic down around the form.

Materials needed to create the vacuum-former include:

- Wood Strips

- Pegboard (2' x 4')

- Plywood

- Shop Vac or similar

Sizes are not critical - the available space in the oven will determine the maximum final size of any pieces formed - so the unit should be built slightly larger than that.

Create a box using the wood strips and plywood, and caulk it to make it airtight.

Drill a hole the same size as the intake hose on your vacuum in the side or bottom of the box, and attach the pegboard to the top of the box. When you place your form on top of the box, then the heated plastic, the vacuum will draw the heated plastic down.

Using an old picture frame, or a cheap one from IKEA, trim your plastic sheet to the same size and heat the plastic in the frame in the oven at 375 degrees, until it just starts to droop. Placing the frame and plastic on oven-safe jars will prevent it from touching the racks or surface of the oven if it should droop too far.

In this photo, the extra airholes are blocked by poster board to maintain the airtight seal.

When creating forms, it is important to remember that it must be possible to cleanly remove the form once the process is complete, so things to avoid include:

- Large vertical surfaces

- Vertical holes

The best form is a pyramid shape, with the smallest details on top and increasing diameters to the base. Consider using a releasing agent to make removing the form easier - a non-stick spray or lubricant for example.

Creating the form itself can be done using foamcore, wood and bondo, aluminum or steel, depending on your available tools and ability. The smoother your initial form, the clearer your final pieces will be.

Welding

If you plan on making metal ramps or wireforms, welding will be required.

In order of quality, here are your welding options:

- TIG: Tungsten Inert Gas arc welding is often employed to make welds on nickel alloys (like stainless steel), magnesium, aluminum, titanium and copper alloys. TIG welds can be made with or without metal fillers, unlike MIG welding, which exclusively employs filler metals to create welds.

- Pros: Pinpoints heat better than MIG welding, allowing for smaller, more precise welding, is a very clean process, creating no spatter whatsoever while a weld is being made.

- Cons: TIG welders are more expensive than MIG welders, and it is a more difficult process to master.

- MIG: Metal Inert Gas arc welding is most often used with steel. MIG welders do not have to start and stop too often while welding, which allows for long, uninterrupted welds. Gas shields the weld, helping to prevent oxidation and spatter.

- Pros: Relatively clean, creating only a little spatter while welds are made, easier for beginners.

- Cons: Possibility of excessive melt-through and incomplete joint penetration or fusion, can be difficult to create a starting arc, welds are known to leave deposits that are heavily oxidized.

- Flux Core Wire Feed: Arc welding without the shielding gas. Uses flux, similar to soldering, to flow metal.

- Pros: Cheapest form of MIG welding as it doesn't require compressed gas.

- Cons: More likely to produce dirty welds due to lack of shielding.

- Brazing: Can be done with hand tools, but it requires a lot of heat for a long period of time in one spot, which weakens the surrounding steel. This makes it more susceptible to warping and bending due to stress. It can work, but it is not nearly as strong as MIG.

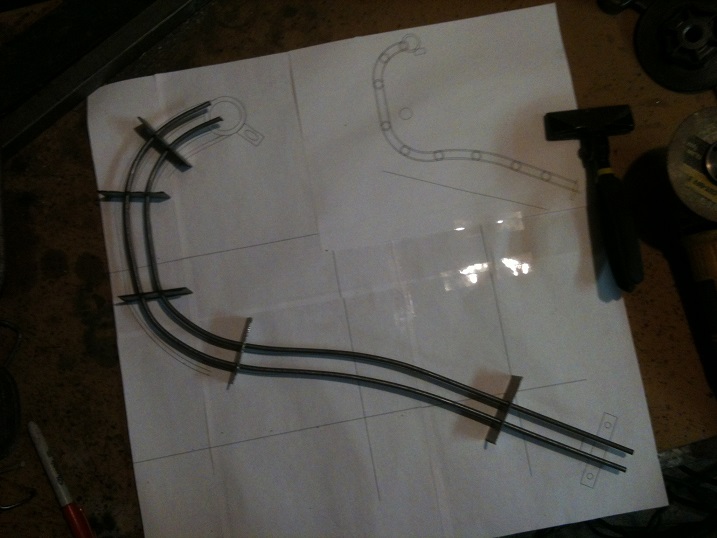

Wireforms

(From Matthew Bonnema's Tutorial on Wireform Fabrication)

One standard convention on modern pinball machines are wireform ramps. They can be made out of 1/8" steel wire which can be purchased at most big box stores. If you don't have access or the skill to use welding equipment, wireform ramps can be fabricated from brass rods and soldered together using a small torch, flux, and solder. Spooky's America's Most Haunted was prototyped this way not only because Ben Heck was already used to soldering, but because brass is a little easier to form than low carbon steel.

Spacers

Spacers help to keep the proper distance between two rails in a wireform while it is being constructed. They can also be used for welding braces. A fair number of these will be needed - two or three per curve - plus a few oversized ones to allow for the grounding clamp from the welder if you're using one.

To make them, just measure the ball and figure out where you want the ball to ride in the rail, then drill two holes the same size as the stock you are planning on using.

Slide the spacers on and match the other wires bends carefully. Make sure to only bend the new wire and not the guide wire.

Use 16 and 20 gauge sheet metal for the spacers - 20 for tight bends and 16 for straightaways. It is easier to slide the 20 gauge down the curves.

If skinning wireforms, put supports on the under side to make them stronger. You can construct ramps by welding sheet metal over the tops of the rails at the ball entry points.

Loops

Loops are useful as entrance and exit points, and cut down can be used as bracing.

Take a piece of 1" PVC pipe and drill a hole centered on the pipe all the way through, roughly the same size of the stock that you intend to use.

Insert the stock all the way through and wrap it around really tightly. It will spring back a little, but if you are using a standard size pinball, it shouldn't be a problem as long as you keep the tension consistent all the way through the wrap.

With an Angle Grinder with Metal Cutting disc, cut as close to the initial bend to get as many loops as you can with out getting any of the curve in the cut.

Take caution! This is a dangerous tool!

A simple way to get really nice and easy loops. Bolt cutters, shears, a hacksaw, or wire cutters capable of cutting the wire you are using can also be used as an alternative to the angle grinder, although the loop ends will not be as clean. Free the loop of wire by pulling down on it slightly and clipping off the bent leg that goes through the pipe. Clip or saw each ring off, using the edge of the last ring cut as a guide.

Create supports by cutting the rings in half to make the supports. A large Side Cutter makes cutting the 1/8" steel stock easy and fast - just make sure to hold on to both pieces because they can fly apart. Eyeball guessing for the center on the rings is fine, but for consistency, measure for center.

Drawings

After making spacers and loops, the best starting point is using drawings made in one of the drawing tools mentioned in the Design section. Match the form to the full-size 2D drawing during construction.

Welding

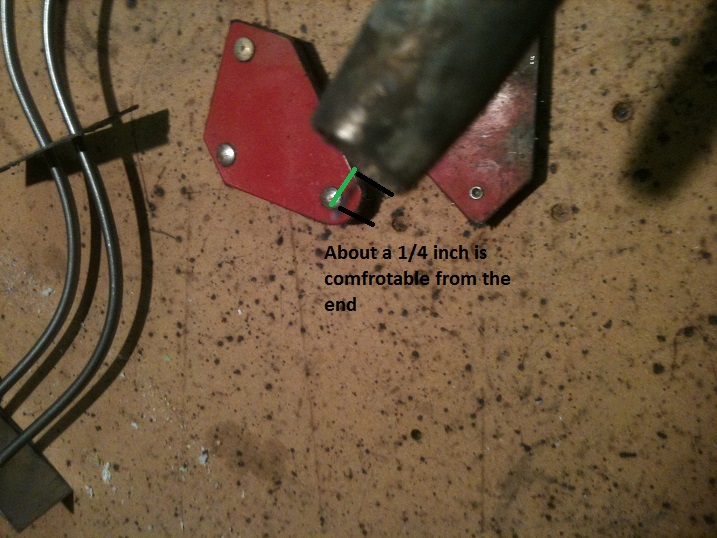

Cut a straight piece of stock, place it on the end of the rail and weld it up with a good tack. This will stop the wireform from twisting out of shape while putting the supports on. Use Welding Magnets (Usually about $3 each from most hardware stores) to hold the wire in position.

Clamp the ground for the welder to one of the jigs - you get a good, dependable circuit and it won't mess you up when you move it.

Time to weld!

Only weld with a Welding Helmet that is tight and won't fall off. If using a auto-darkening helmet, test its function before starting to weld. It should darken from the spark of a lighter.

First test the feed of the welder by pushing the button and watching how smooth the wire comes out. Having a jumpy feed can ruin a weld pretty fast. Then trim the wire to a comfortable length.

If the wire is too long, it will make spatter all over, while if too short, it could miss the joint and/or clog up the tip of the welder.

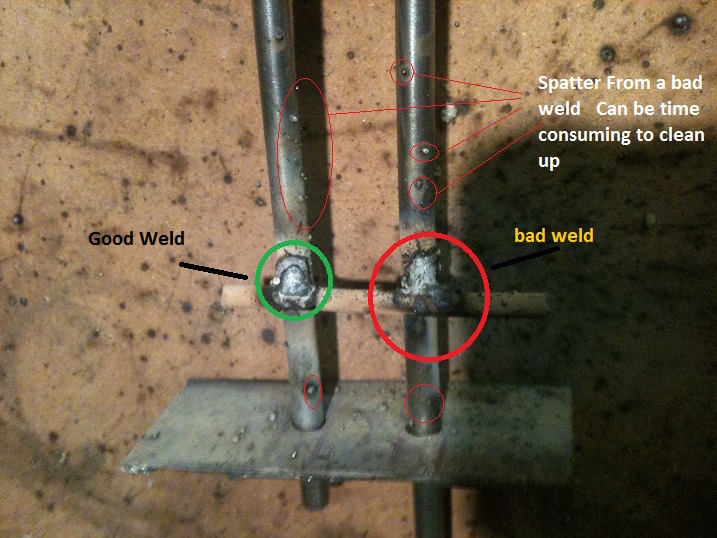

A good weld has clear signs of even heating and penetration through both parent metals (the grayish circle that surrounds the weld).

The bad weld example was done by having the wire overfed or having the wand to far from the surface. This creates a large amount of spatter, which on pinball rails is difficult to clean up due to the sizing.

It also has a distinct noise when done incorrectly - it sounds like bacon popping. A good weld has a consistent buzz sound.

After measuring where you want each support to go on the wireform, flip the rail over and set a half ring that was cut earlier across the two rails, using a magnet to hold it in place.

Make sure the ring is lined up with both sides of the rail. It should flow with curves and should be evenly placed.

A good welding technique to use is called Pushing the puddle. It is basically starting on the thicker material and pushing the molten puddle back into the thinner cross material.

Top Rail

With all the supports are welded, it's time for the top rails.

Take the PVC pipe used to make the rings from earlier and mount it to your workbench. Put the stock where the bend should be under the pipe and pull up, keeping a lot of force at the base.

Take the bent stock and lay it across the rail. Mark where it should get the first welds.

Go down the entire length of the wireform, bending the top rail wire by hand as close as possible to the form without welding. Welding and bending one after the other would cause the areas that have been welded to be much softer from the heat of the weld. This is called Annealing, and your top rail bends will not match the cold bended main rail.

Finishing

Every now and then, bring your wireform back to the machine and test fit to make sure it is not getting warped from the heat of the welder.

During the fitting, mark areas for adding supports to hold the wireform.

After all the welding is complete, quickly run the whole wireform on a Fine Finishing Wire Wheel to clean it up and ready it for powdercoating or plating.

To see these parts powder coated and installed, see the DeadPin machine in the Custom_Games section.

Stencil Cutter

A Stencil Cutter is similar to a computer printer, except instead of printing it uses a small blade to cut paper, cardstock, vinyl, fabric, and other material. A good quality unit is the Sihouette Cameo, available from Amazon.

There are two steps to creating quality stencils:

- The stencil material to cut with the Cameo

- The transfer tape used to transfer the weeded stencil to the part being painted

Weeding is the process where you remove the parts of the cut stencil you don't need. The best material to use is Gerber 15 SM-4 GERBERMASK 1 ULTRA as it is thick enough to not clog the Cameo but allows for very fine detail. This is a medium tack pressure sensitive stencil material that has a slightly grainy white surface. It has a pressure-sensitive adhesive designed to work with a float solution like water with dish soap.

For the transfer tape, use RTape Clear Choice AT65 which is a good general-purpose medium tack tape.

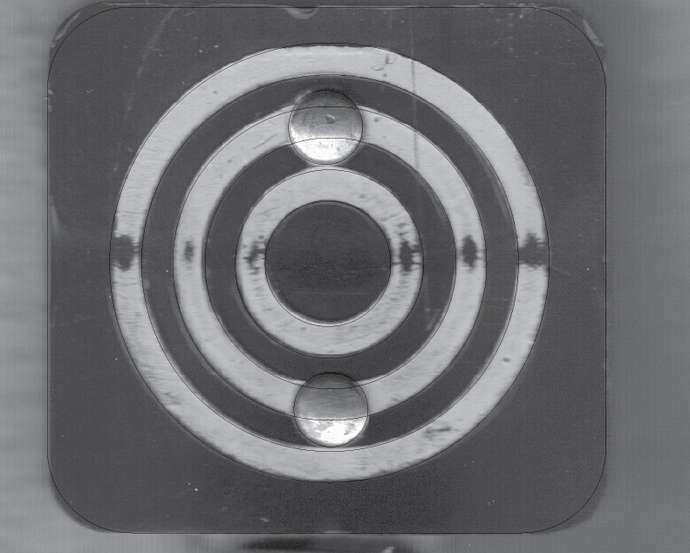

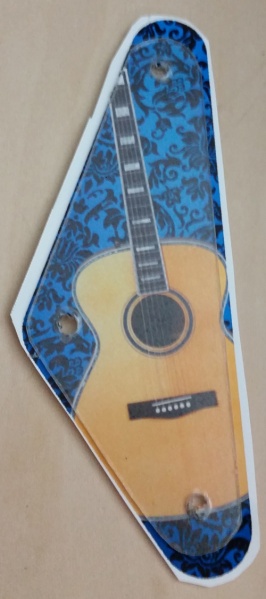

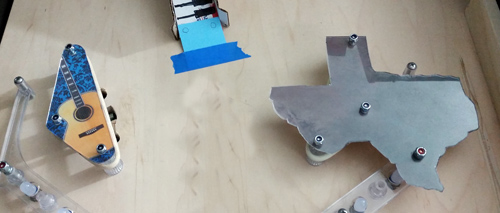

If working with an existing part, use a scanner to get a 1:1 image of the item to allow for vector tracing. Then bring the scan into a vector editor like Illustrator or Inkscape, and create the vector outline of where the cuts should be made for the stencil.

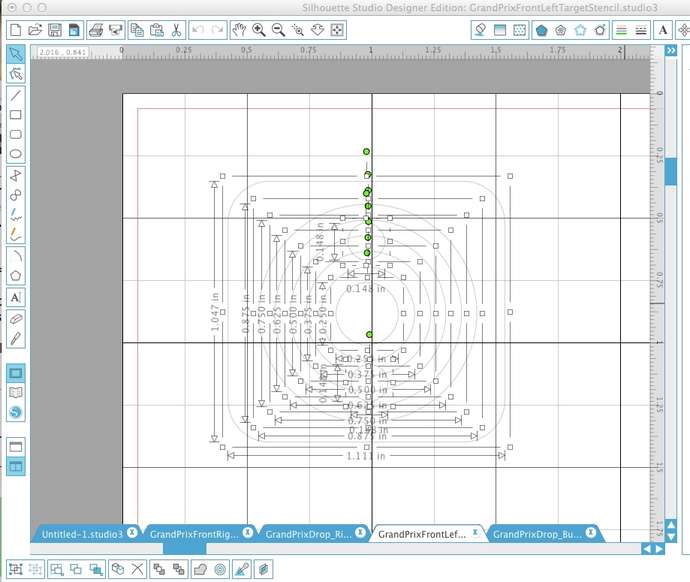

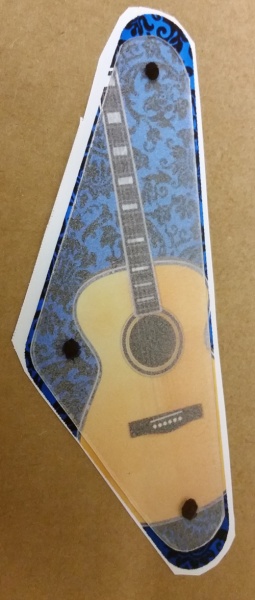

Once the vector is complete, the drawing can be imported into the Silhouette software bundled with the cutter to create a cut plot.

At that point, the stencil can be cut and weeded.

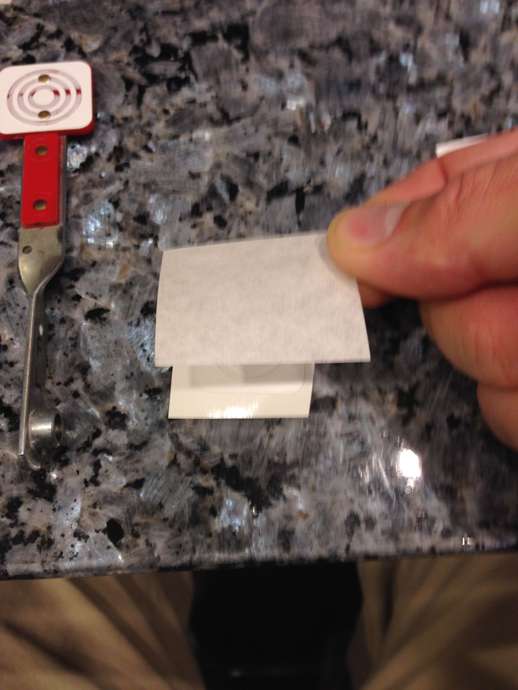

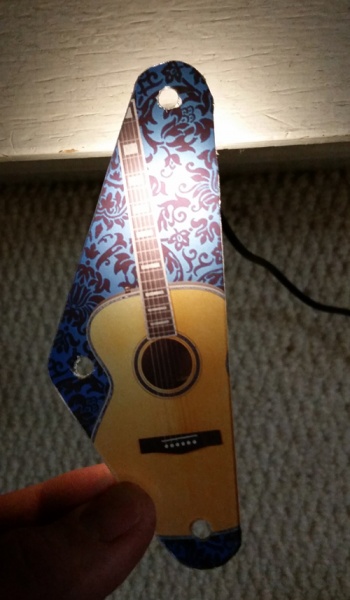

Apply the transfer tape to the stencil material, which allows it to be peeled off the backing and then applied to the surface to be painted.

Pull the transfer tape off, leaving the stencil in place.

At this point the part can be painted. Once the stencil is removed, the finished part is ready for installation.